Battery manufacturing

Ensure the highest quality and performance of rechargeable batteries

The green transition is accelerating the development of new innovations and applications for secondary batteries. Lithium-ion (li-ion) and sodium-ion batteries, and other battery chemistries, are used for powering electric vehicles (EV), battery energy storage systems (BESS), and a wide and growing range of consumer goods.

In manufacturing, electrode metals, electrolyte and manufacturing chemicals react to moisture, which requires stable and low or ultra-low dew point conditions in dry rooms, dry booths, glove boxes and inert atmospheres. Maintaining low or ultra-low dew point conditions is essential for safety, yield, and efficiency.

Manufacturing facilities - especially gigafactories - are enormous, and drying these controlled environments to specified dew points requires significant energy, as well as some of the processing steps, such as cathode drying.

How to operate dry rooms cost-efficiently and sustainably

1. Fast response is the only way to go

Any downtime in manufacturing is costly, therefore Vaisala’s fast-response, highly accurate dew point probes bring measurable advantages in dry rooms and dehumidifier units.

Don’t wait hours or days for the probes to stabilize to continue safe production.

2. Simple is beautiful

Vaisala’s probes are user-friendly, durable, compact, easy to operate, and suitable for various scales of manufacturing. Set-up is easy, as is maintenance.

Choose reliability and simplicity over complexity and uncertainty.

3. Ecosystem thinking is wise

Benefit from Vaisala’s dew point probes and other measurement parameters hosted by the Indigo transmitters.

With Vaisala you can easily ensure comparable measurement results across your entire production process.

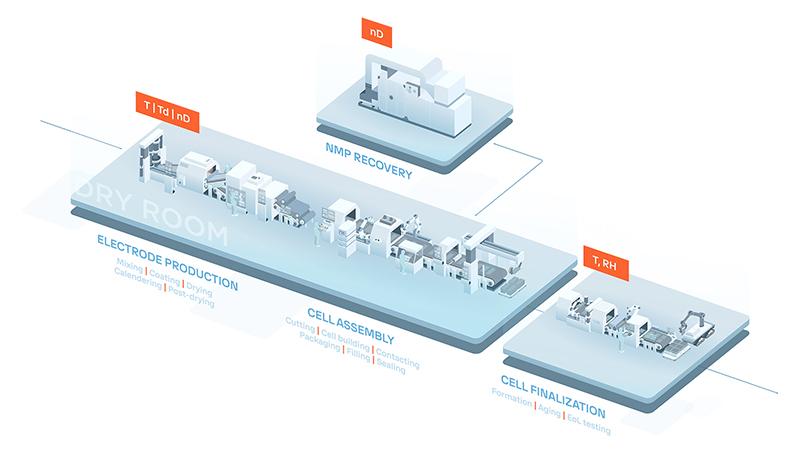

Trusted partner for midstream operations of lithium battery manufacturing

Vaisala offers key measurement parameters for critical operations in manufacturing.

Measure accurately and in real-time:

- temperature (T)

- dew point (Td)

- relative humidity (RH)

- chemical concentrations (nD)

The world-class measurements with technologically best-suited products especially for ultra-dry conditions and for critical filling and sealing operations are only available from Vaisala.

Technology comparison

Review how Vaisala's dew point probe compares to CRDS' (Cavity Ring-Down Spectrometer)

and Chilled mirror transmitters in the most demanding operating environments, such as

rechargeable battery and semiconductor manufacturing.

| Vaisala’s dew point probe | CRDS | Chilled mirror transmitter | |

| Td measurement range* | -80 °C…+20 °C | -100 °C…-50 °C | -70 °C…+20 °C |

| In-situ measurement | Yes | No, requires sampling and a large pressure difference | No, requires sampling |

| Td accuracy in laboratory conditions* | +/-2 °C | +/-0.2 °C | +/-0.2 °C |

| Pressure range* | 1…50 bar | 1…5 bar | ~ 1 bar only |

| Dependency of atmospheric conditions | Not dependent | Dependent. Stable atmospheric conditions required. Sampling might generate errors in non-laboratory environment. | Dependent. Minimum dew point will raise if the ambient temperature increases. Sampling might generate errors in non-laboratory environment. |

| Response time* | Minutes | Tens of minutes | Hours |

| Sensitivity | High | Low (cannot detect quick changes, averaging measurement) | Low (cannot detect quick changes, averaging measurement) |

| Size | Small and light. Fits easily to multiple locations | Mid size, about 10 kg | From big and heavy to mid size |

| Operator to provide regular service | Not required | Not required | Required |

| Components requiring service | Not required | Not required, if in clean environment | Required (e.g., Peltier) |

| Local calibration/ support available | Yes | Unlikely | Unlikely |

| Dependency of background gases | Minor | Potentially strong | Potentially crucial |

* Typical values in battery and semiconductor manufacturing

Exclusive webinar with The Volta Foundation

Join to learn the best practices for installing, cleaning, and optimizing moisture sensors across various environments—from HVAC systems and R&D labs to pilot lines and full-scale manufacturing.

Dry room monitor and control

The goal of a dry room is to provide a safe working space free of contaminants, with moisture being the most significant. The typical dew point temperature is around -40°C Td/f, but can be as low as -70°C Td/f.

Manufacturing areas requiring dry conditions can be as large as 10 000 m² and require significant volume of air to be heated, cooled, and dried. Steady dry conditions are achieved and maintained by delivering a controlled volume of air at specified dew point. The desired dew point is achieved in the dehumidifier unit by adjusting the airflow speed across the desiccant wheel, and aided by Vaisala’s dew point probes. Vaisala’s fast-response dew point probes detect any humidity changes within a drum rotation without averaging, enabling true real-time control.

Vaisala's probes optimize dehumidifier unit efficiency by providing accurate, real-time data, reducing energy consumption, and contributing to more cost-effective battery manufacturing.

Efficient room-wide monitoring for maximum process efficiency

By placing the probes strategically and at adequate intervals, the dry room or cleanroom can be monitored efficiently, ensuring comprehensive control of your entire room, whatever the size.

The DMP1 is optimal for maintaining process reliability and correct dryness levels in battery and semiconductor manufacturing with Indigo300.

Midstream applications

Anode drying

Anode drying with controlled dew point helps form a stable Solid Electrolyte Interphase (SEI) during the initial charging cycles. This SEI layer is crucial for the battery's performance and safety.

Vaisala’s dew point, humidity, and temperature measurements control the drying segments in a dryer. This helps to maintain product quality and performance while protecting battery materials and components from moisture.

Although anode drying is faster due to solvent’s boiling point - typically water-based - optimized process control can lead to energy savings. Contact us to discuss how.

Cathode drying

Successful cathode drying prevents harmful side reactions and corrosion, helps to create a porous structure that facilitates optimal ion and electrolyte movement, and ensures overall suitable electrochemical performance by evenly distributing the binder within the electrolyte. Cathode drying is one of the most expensive processing steps, especially if not properly managed and optimized.

Vaisala probes can be used at different stages of the drying process, even in drastically different operating environments, including aggressive chemical solvents such as N-Methyl-2-pyrrolidone (NMP), and very high temperatures. Selecting Vaisala for the demanding conditions ensures accurate measurements and provides comparable results across different drying steps.

Take control of the cathode drying processing and increase yield.

Dehumidifier control

Vaisala's dew point probes are designed to optimize the efficiency of dehumidifier units (DHUs) in battery manufacturing, significantly reducing energy consumption and operational costs. Vaisala’s fast-response dew point probes are used to establish a closed control loop with the high-end dryer, allowing the process to be fully optimized.

Learn more about products:

Glove boxes

Glove boxes are an essential tool in battery manufacturing providing a controlled, sealed, and inert atmosphere maintaining low levels of moisture and oxygen, and protecting the lithium, electrode, and other materials from reacting with and degrading from moisture or oxygen.

Maintain desired low humidity levels and keep humidity in strict control during glovebox operations and electrolytes safe from decomposing, while ensuring quality, safety, and performance of battery components with Vaisala’s small-in-size and integrable measurement probes.

Direct installation in the glove box combined with the probe’s chemical tolerance and fast reaction time enables extremely fast sequence control.

Dry booths and other inert atmospheres

Some process steps in rechargeable battery manufacturing might require extra dry conditions beyond the regular dry room with a controlled, sealed atmosphere.

Rely on Vaisala’s accurate measurement results and small-in-size probes that are at home when precision is needed. Get to know the recommended products.

The world-class measurements with technologically best-suited products especially for ultra-dry conditions and for critical filling and sealing operations are only available from Vaisala.

DMP7

NMP and other solvents

N-Methyl-2-pyrrolidone (NMP) is essential for producing high-performance lithium-ion batteries. It effectively dissolves PVDF (polyvinylidene fluoride) binders, creating a uniform slurry that ensures consistent dispersion of active materials and an even coating on the electrodes. This is key to achieving optimal battery performance.

Vaisala’s chemical concentration measurement solution, the Vaisala Polaris process refractometer, enhances efficiency and sustainability in battery manufacturing by ensuring that costly and toxic NMP is effectively recovered, minimizing chemical waste and reducing environmental impact – helping you cut costs while supporting a more sustainable production process.

Learn how Vaisala’s process refractometers bring savings, advance sustainable operations, and enhance product quality.

Download application note

Reliability and simplicity in your critical battery manufacturing measurement points

Make smart choices, and reduce your workload and uncertainty in battery manufacturing by selecting accurate and reliable measurement instruments.

The benefits of a rapidly reacting probe in a battery manufacturing dry room

Drying is one of the costliest operations in a battery manufacturing dry room. Drying is also a delicate act as overdrying is expensive and underdrying is dangerous.

Learn why it all can fail if a dew point probe in a dryer reacts slowly.

WHY VAISALA

SAVE ENERGY

Save energy in all dryer operations of a dry room. Manage dryer precisely, and benefit from the probe’s rapid response time for immediate dryer adjustments.

LOW DEW POINT COMPATIBLE

Monitor dry room conditions with Vaisala Indigo products and ensure consistent and on-target operations for both standard and specialized conditions. High-performance Vaisala Indigo products are already suitable for the dry requirements of the future.

HOT/DRY/CHEMICAL PROCESSES

Vaisala products are good with everything as the measurement probes are designed to be in the most demanding environments.

GATHER DATA AND PROCESS SAFELY

Gather data with Indigo products, equip dry room with local screens, and feed data to the supervisory control and data acquisition system (SCADA) for immediate adjustments and safe processing.

FULL OFFERING

Versatile measurement solutions, including measurement range, temperature, sampling solutions, support for various digital outputs, and probes with chemical tolerance.

Ecosystem execution in design enables mixing and matching probes meeting specific needs.

SOLID STATE

Solid-state, the next generation batteries will require even stricter dew point conditions down to -80°C Td/f, to which Vaisala already has offering. Get to know the DMT152.

Researching solid-state and beyond

Lithium-ion (Li-ion) batteries, lithium-sulfur (Li-S) batteries, sodium-ion batteries, and solid-state batteries.

Battery technology is evolving at an unprecedented speed in the quest to find more powerful, safer, and smaller products to satisfy the ever-growing demand. Despite the new advances, these new technologies are even more sensitive to humidity and require accurate control and monitoring.

Vaisala has ready solutions for R&D, laboratory, and scaling-up manufacturing. In cases where a measurement need is identified but lacks a suitable instrument, we find solutions.

Partner with the most trustworthy measurement provider for reliable results and safe experiments, and prepare future developments with the best-in-class humidity and dew point probes.

Hydrometallurgical recycling

Valuable metal recycling is one of the key aspects of reaching a circular economy in secondary battery manufacturing. New innovations and technologies are emerging to enable high metal recovery rates economically and sustainably. One such innovation is the hydrometallurgical recycling process that recovers metals through chemical process, such as leaching.

Moisture control remains critical throughout recycling, as lithium reacts with moisture and requires precise dew point monitoring to ensure safety and efficiency. Vaisala’s products provide critical data, prevent material degradation and ensure safe processing conditions.

Ensure safe processes with Vaisala.

Battery manufacturing related products

Dew Point Probe DMP1

Miniature Dew Point Transmitters DMT143 & DMT143L (Long)

Dew Point Transmitter DMT152

Barometric pressure measurements with Indigo520 Transmitter

Indigo80 handheld measurement device

Relative Humidity and Temperature Probe HMP7

Dew Point and Temperature Probe DMP5

Dew Point Probe DMP6

Dew Point and Temperature Probe DMP7

Dew Point and Temperature Probe DMP8

Intrinsically Safe Humidity and Temperature Transmitter Series HMT370EX

Vaisala Polaris™ PR53GC and GCEX Compact Process Refractometers for ordinary and explosive areas

Vaisala Polaris™ PR53GP and GPEX Probe Process Refractometers for ordinary and explosive areas

Try our dew point instrument finder

Upstream processes in lithium-ion battery manufacturing

Measure aggressive chemical concentrations in mining operations.

Downstream processes in lithium-ion battery manufacturing

Monitor temperature and relative humidity seamlessly in downstream operations.

Contact us

Interested to receive more information on a specific application or product? Drop us a line, and we'll get back to you!