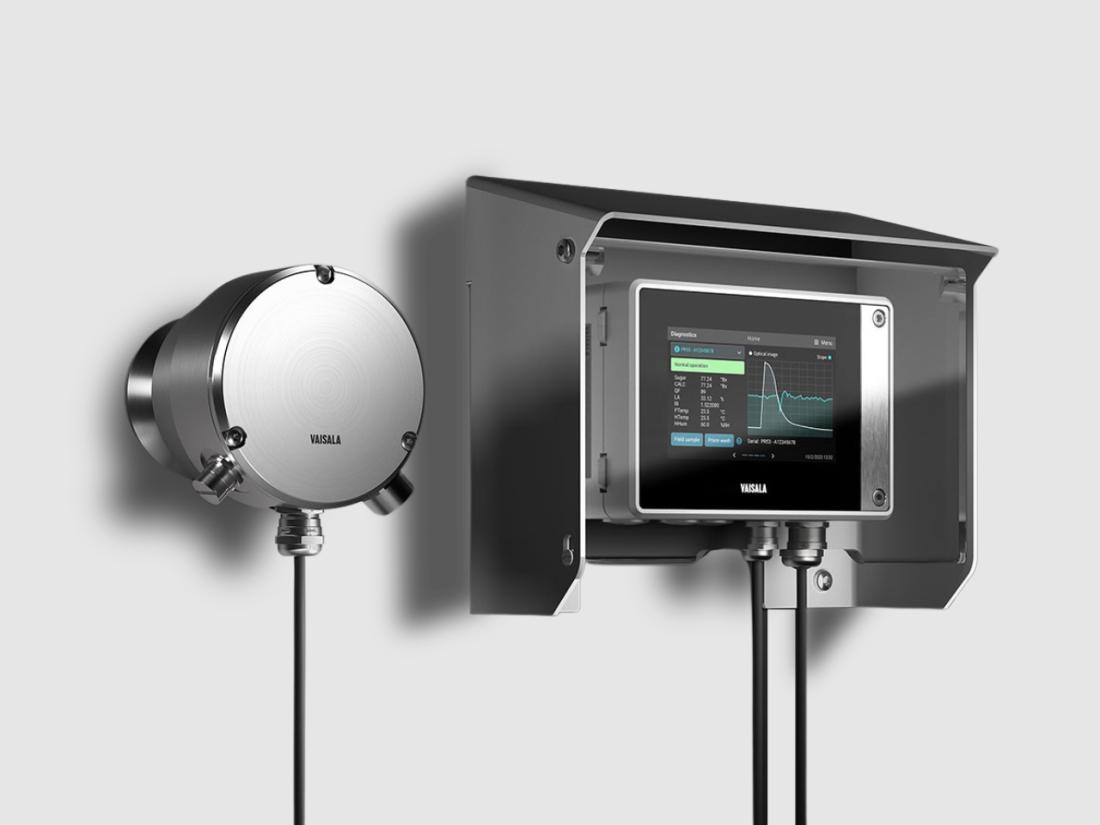

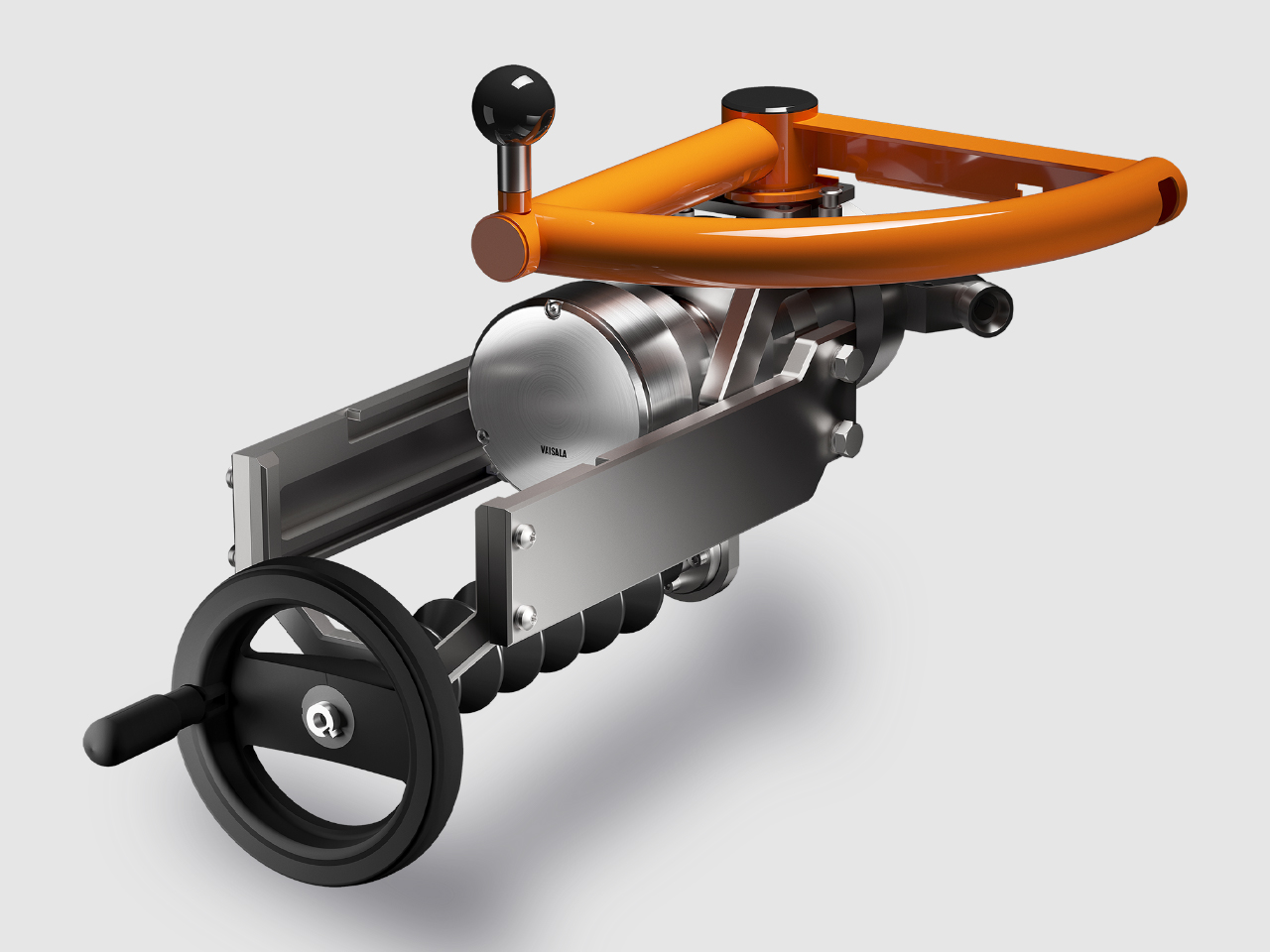

Vaisala Polaris process refractometers are used for inline liquid measurements to enable efficient process control and industrial automation. They are stand-alone and smart devices that measure and indicate concentration units and diagnostic information. They provide 4-20 mA or Modbus RTU outputs to connect directly to the control system. All process refractometers can also be connected with the Indigo520 for process refractometers for physical user interface and expansion of features.

The Vaisala Polaris refractometers represent the latest, 5th

Our significant investments in research and development have earned us global recognition for delivering innovative, dependable, and top-quality products.