Continuous Monitoring System Services

We offer a broad range of services to support our environmental monitoring systems and components: software, sensors, and network connectivity devices. Along with system deployment services and training that provides your staff with an in-depth understanding of the system, CMS services ensure your monitoring system is efficient, effective, and meets the most stringent compliance requirements.

Our service offering for Vaisala monitoring systems

The Calibration Care Agreement for field service is a multiyear maintenance plan for the calibration of Vaisala products. Benefits are fixed pricing for the length of the agreement and advanced on-site scheduling.

On-site standard and accredited calibrations include:

- ISO 9001 or ISO/IEC 17025 accredited single/multi-point calibrations

- Preparation and logistics of reference devices

- Device functionality check

- Calibration date update

- Traceable calibration certificate

- Service report

- viewLinc calibration alarm acknowledgement (if applicable)

- Optional battery replacement for wireless devices

- Fixed calibration costs for up to 3 years

Calibrations are performed by Vaisala Certified Engineers.

Product documentation

Continuous Monitoring System Services Related Products

viewLinc Monitoring, Alarming and Reporting Software

VaiNet Wireless Temperature Data Logger RFL100

Temperature and Humidity Data Loggers DL2000

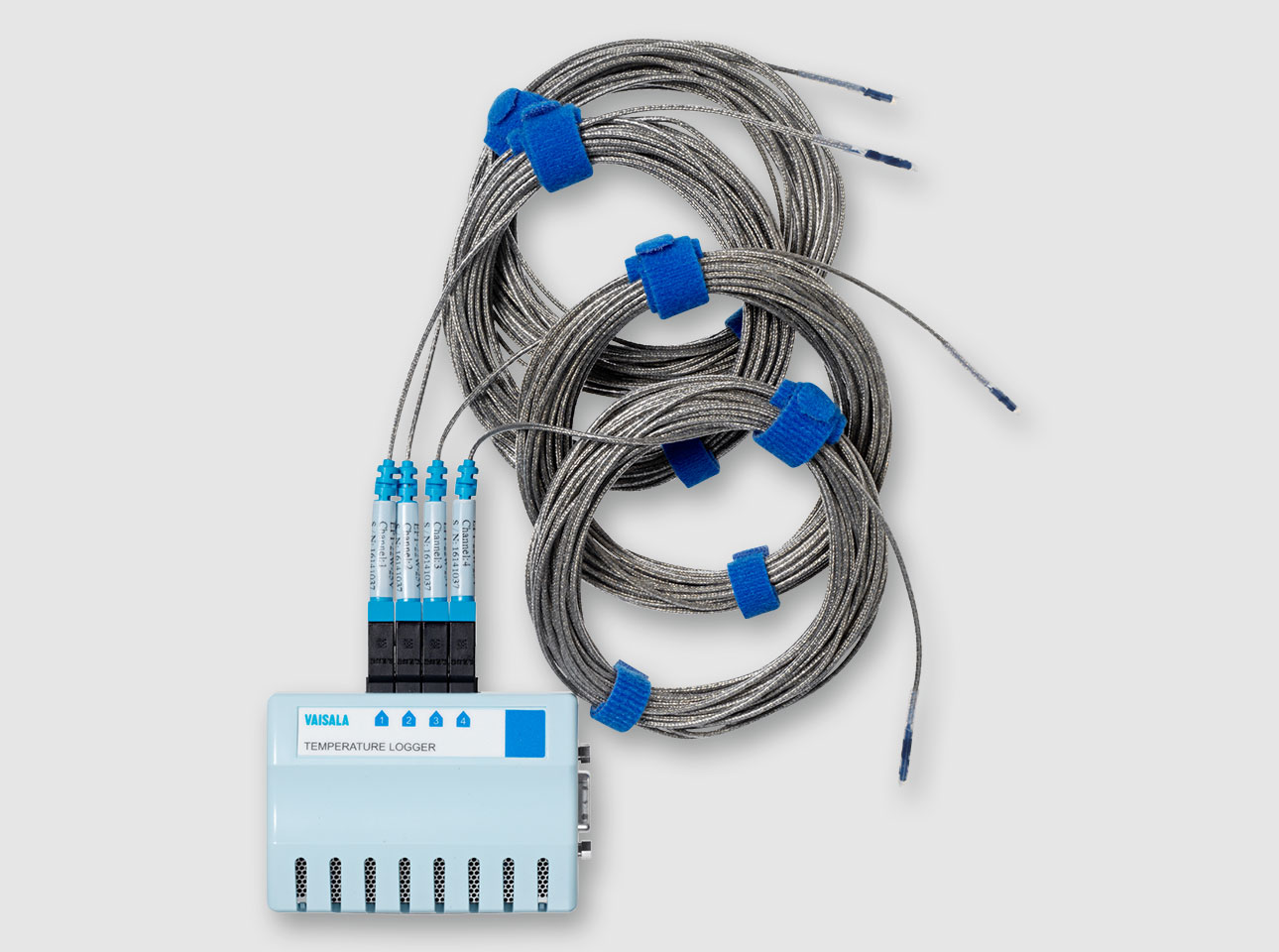

Temperature Data Loggers DL1016/1416

Vaisala serves almost all of the top 50 pharmaceutical companies

We are a strategic partner for more than 3,200 life science customers, in 57 countries,

with over 800 installed systems including GxP-regulated warehouses, laboratories,

cleanrooms, incubators, refrigerators, freezers, and distribution centers.

Customer Stories

Contact request to Vaisala Sales

Interested in receiving more information on the life cycle services? - Contact our sales representatives.