How to measure crucial process parameters for efficient spray drying

Spray drying is a common sight in the manufacture of dairy products like whey protein concentrate (WPC) and lactose as well as in pharmaceutical manufacturing. The process creates dry powder from a liquid or slurry in a single step by quickly drying it using hot gas. Stable and accurate measurements of humidity, total solids (TS), and temperature, can help you make big savings in energy consumption and costs without compromising end-product quality.

Monitoring the right parameters is critical

Spray drying is used in a variety of different industrial production processes to:

• increase product shelf life

• make products easier to handle during packaging, transportation, and storage

• prevent microbial growth

• ensure product quality

• save energy

• increase yields

To optimize your spray drying process there are a few key process-critical parameters to keep an eye on: the soluble solid content of the feed to the dryer (typically measured in Brix or total solids (TS) and the inlet and outlet air humidity and temperature.

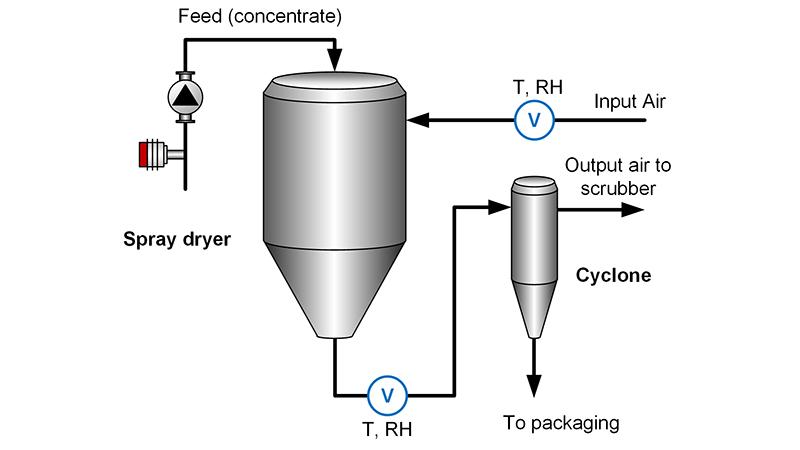

Image: Accurate Relative humidity (RH), temperature (T) and the feed line Total solids (TS) measurements are critical for ensuring efficient spray drying

Spray drying monitoring using stable, reliable, and accurate measurement instruments will ensure that your product is dried sufficiently to avoid microbial growth – which is particularly important with food products – but not overdried, which can negatively impact product quality and result in excessive energy consumption and costs. With energy costs currently skyrocketing, ensuring efficiency is at the top of everyone’s agenda.

Optimizing processes with accurate Brix and TS measurements

Manufacturers can improve productivity by automating and optimizing their processes using in-line Brix and total solids (TS) measurement provided by the Vaisala K-PATENTS Sanitary Refractometer PR-43-AC.

For example, in whey protein and lactose production – important food supplements that are commonly concentrated and preserved as powder – reliable, accurate in-line concentration measurement helps to control and adjust concentration levels after ultrafiltration and at

the evaporator inlet. Precise concentration measurement from the evaporator outlet helps to optimize energy consumption and ensures the correct feed product concentration to the spray dryer or crystallizer.

In yeast production, where spray drying is used to dry the yeast extract to a fine powder or granulated particles, in-line concentration measurement can be used to control dilution of molasses at the initial stage, control fermentation progress, and measure the concentration of yeast extract to ensure the target dry solids level is achieved.

Save energy and costs with accurate humidity and temperature measurement

As well as spray drying, humidity measurements are a key factor in optimizing a variety of other high temperature drying processes, including fluid bed drying and baking. When spray drying whey Vaisala’s humidity and temperature probes can be used to measure humidity and temperature in the dryer’s inlet and outlet air.

The inlet air humidity data is used to control the process, while the outlet air humidity data correlates with the moisture content of the powder. This means it can be used as an indicator of the final product quality. Finding the perfect balance saves time and energy by avoiding overdrying.

If you want to see for yourself how accurate humidity measurements can help you increase energy efficiency and improve quality and yields in your process, try our interactive drying simulator.

Add new comment