Spray Drying Monitoring

Optimized spray drying saves you energy and costs

When it comes to drying of food, for example, most experts agree that it is important to dry it enough to avoid microbial growth and to keep the product safe. On the other hand, minimizing the drying process will save you on energy and costs, as seen in the drying simulator. The key is to increase the input volume or the humidity levels just enough to minimize energy usage but not too little so that the end-product quality does not suffer.

As to what levels to set, this will depend on the product attributes, such as the desired aw value of the end-product. Since the optimal input volume varies based on the product you’re drying, a universal drying theory does not exist. It is basically up to the manufacturer to define the optimal exhaust air relative humidity or dew point levels. But in the drying phases, regardless of the level desired, knowing the values of parameters like sticky point, adsorption isotherm and glass transition point (Tg) and keeping the conditions stable with accurate and stable HUMICAP sensor measurement technology is essential and a key methodology for developing more cost and energy effective manufacturing processes.

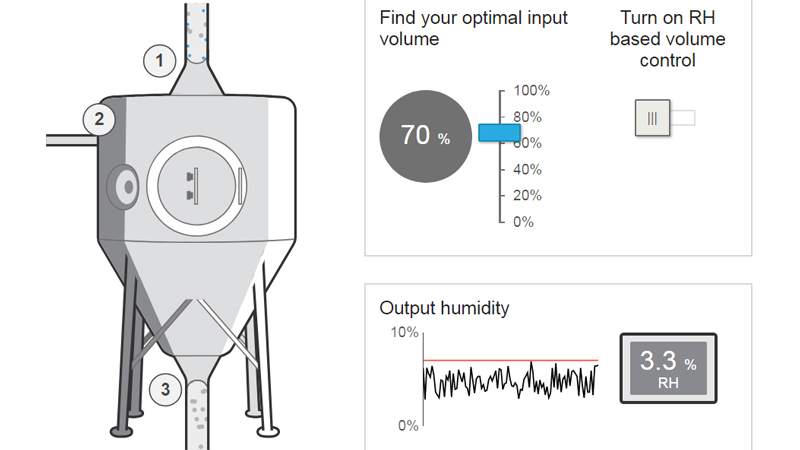

Drying Simulator

Finding the optimal conditions and being able to keep them stable is the key to lower cost and energy efficient manufacturing. Try out our interactive drying simulator to understand the way exact humidity measurements can lead to more efficient energy use and higher yields.

Spray drying related products

Dew Point and Temperature Probe DMP7

Dew Point and Temperature Probe DMP8

Indigo200 Series Transmitters for Vaisala smart probes

Indigo500 Series Transmitters

Relative Humidity and Temperature Probe HMP7

Humidity and Temperature Probe HMP3