How to improve humidity measurements in extremely dry environments

Case example of high-purity gases in process industry

Some of the most challenging industrial processes, such as pure gas production or semiconductor fabrication, require very accurate measurements of trace moisture levels.

Usually, the best measurements are considered to be performed in laboratory environments. However, there are sources of uncertainty that are linked to the sampling, for example, contamination, averaging, and tubing. In this article, we demonstrate sampling-related uncertainty sources in laboratory environments compared with online measurements.

It is typically understood that the best way to achieve high accuracy is to buy a measurement instrument with the best specifications. For humidity measurements, this means an analyzer-type instrument since, in theory, they are very accurate. However, analyzers, are more expensive than more robust industrial instruments. They are also more sensitive to ambient effects and thus require specific and stable conditions.

Usually, analyzers do not measure directly from the process. Rather, a gas sample is taken, led to the analyzer, and then wasted. The problems with sample gases are common in all measurements:

- They may not be representative of the actual process conditions.

- They may also be affected by external factors in sampling and analysis.

- They may be affected by leaks or even be the source of leaks.

For example, imagine weighing some powder. If the powder gets wet from rain between sampling and weighing, the sample will not reflect the true weight and composition of the powder. Similarly, water vapor can easily alter increase the humidity of a gas sample, leading to inaccurate results even with the most advanced and brand-new instruments.

How to improve humidity measurements in extremely dry environments

Experiments

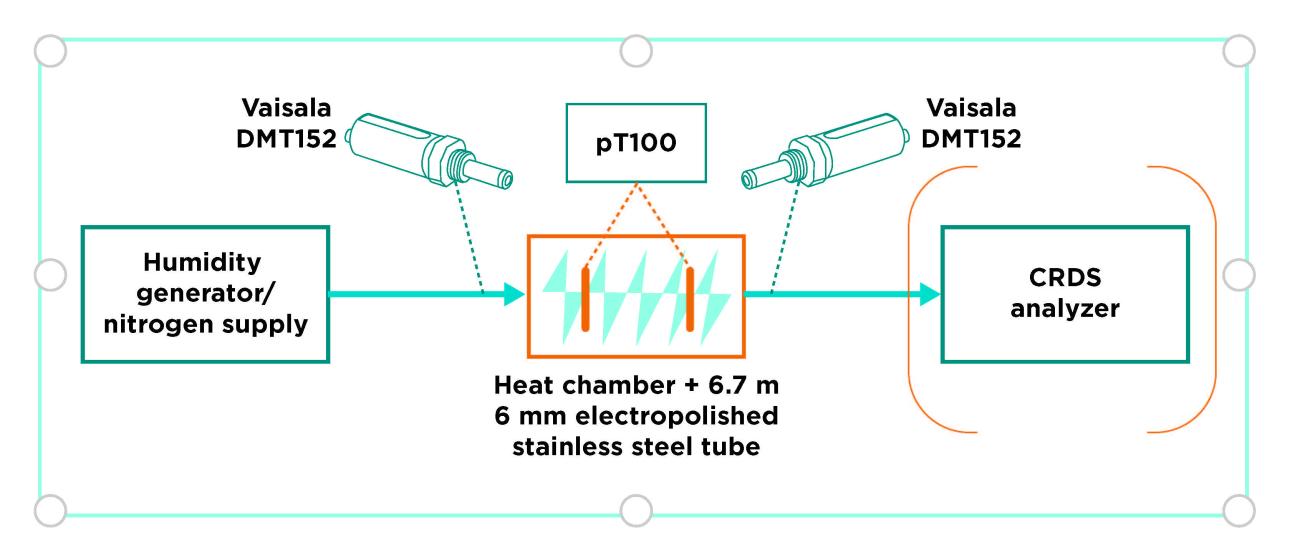

To demonstrate the problem and study its impacts, we built a test set-up (demonstrated in figure 1). The basic idea in the set-up was to have constant humidity, which was then disturbed by changing the temperature of tubing across a range from 20 °C to 27 °C. In theory, this would result in an adsorption/desorption effect, which influences the total amount of water vapor exiting the heat chamber. Similarly, a sampling tube out from the field to the measurement laboratory could be exposed to outdoor weather and thus to temperature changes. On a smaller scale, the varying indoor temperatures could impact similarly. During the experiments, gas pressure was kept within a range of 1 bar(a) to 2 bar(a) and the flow rate was at all the times less than 1 l/min, which corresponds with the flow rates of analyzers.

The set-up was comprised of a humidity generator, two Vaisala DMT152 dew point instruments, a heat chamber with a 6.7 m electropolished steel tube, and a CRDS analyzer. A DMT152 dew point instrument was placed before and after the heat chamber (Figure 1). Tubing from the second DMT152 to the analyzer was kept as short as possible to minimize ambient effects between the DMT152 and the analyzer. The temperature of the heat chamber was monitored with two temperature sensors.

Results

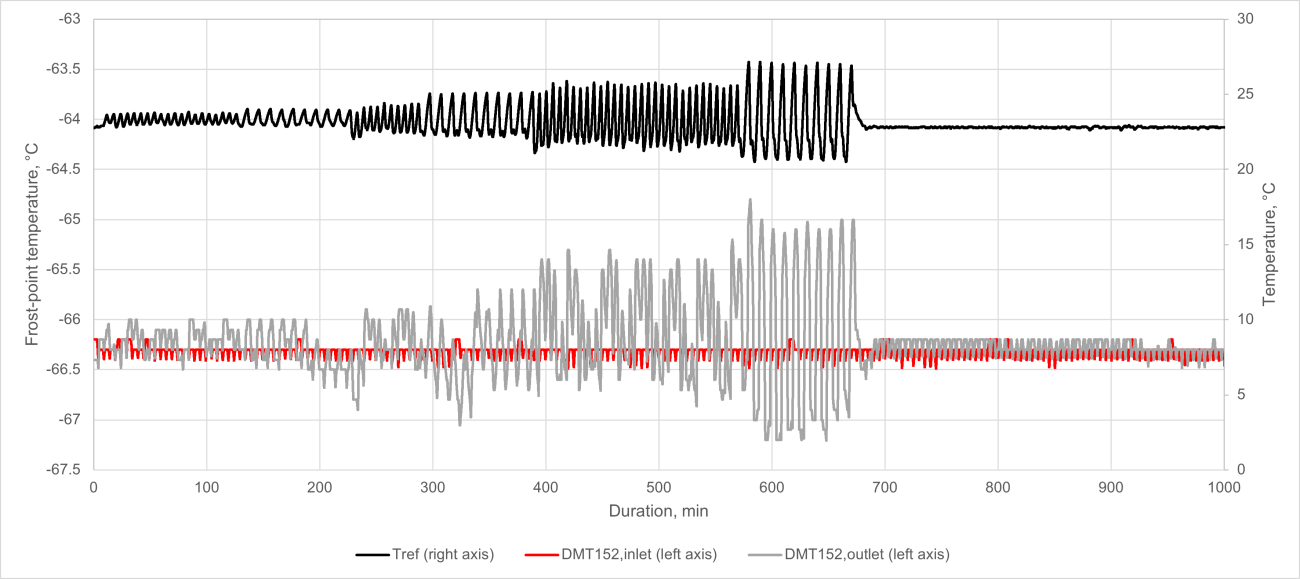

Multiple measurements were performed with different pressures, flow rates, and humidity. The heat chamber was controlled the same way through each of the experiments. (See Figure 2.)

In Figure 2, as the temperature (black) is disturbed more and more, the more the DMT152 at the outlet detects noisy humidity while the inlet humidity is constant through the measurement. At the end of the measurement, the temperature is stabilized to laboratory temperature and both DMT152 instruments are again stable and indicate the same frost point temperature. This picture clearly demonstrates the effect of sampling tube temperature stability on output humidity - and hence to humidity measurements.

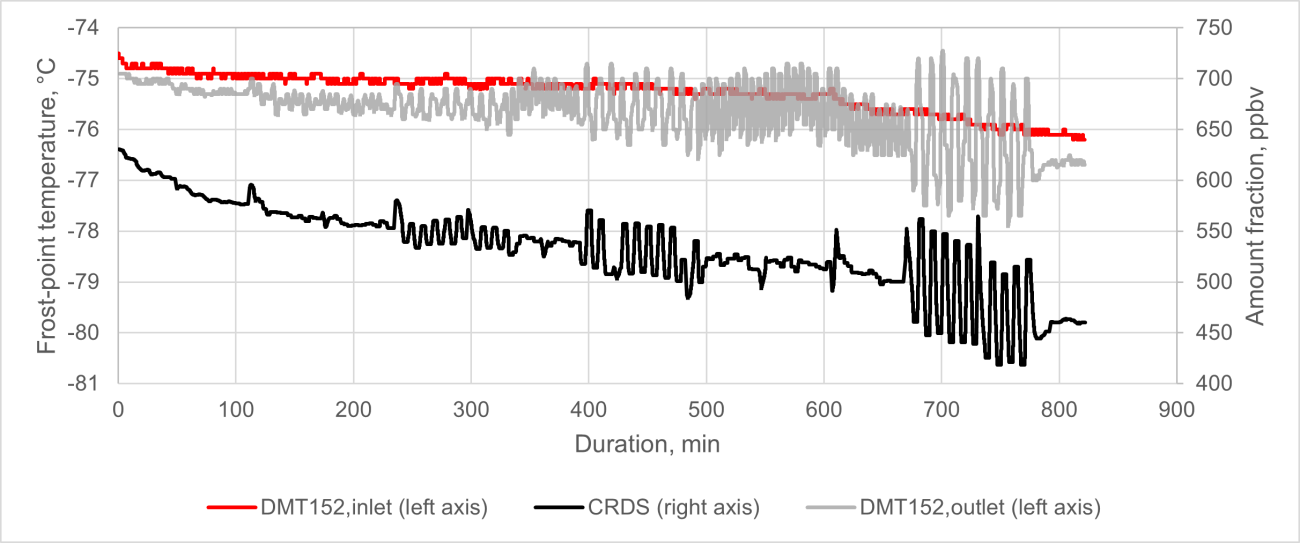

Another measurement is drawn in Figure 3. Here, inlet humidity was not as stable as in Figure 2, but both DMT152 instruments and the CRDS analyzer indicate a similar trend. However, in Figure 3 the inlet humidity is much less noisy in comparison to the CRDS analyzer or the DMT152 at the outlet. In fact, humidity at the outlet changes so much that neither the DMT152 nor the CRDS analyzer indicates the correct inlet humidity, and in fact, both are out of their specs. However, here the instruments are fully functional, and their performance is known to adhere to their specs; the problem is with the sampling tube. The changing temperature causes an adsorption/desorption phenomenon which results in varying humidity in the outlet of the sampling tube.

Results of the measurement campaign indicated:

- Maximum frost-point temperature change caused by adsorption/desorption was over 4 °C.

- Flow rate impacts: greater flow, bigger noise.

- The more temperature changes, the bigger the adsorption/desorption effect in tubing.

- The lower the humidity is, the greater the relative effect is.

Key takeaways

In this article ambient effects to sampling were tested. If the measurement environment or sampling is not ideal, it may have a significant impact on the measurement results. As shown in Figures 2 and 3, the more affordable DMT152, located at the inlet, outperforms the pricier analyzer thanks to the better representativity of the inline process measurement. Therefore, it is recommended to conduct measurements directly at the spot of interest and minimize the use of sampling whenever possible. This approach is also significantly more cost-efficient, thanks to the simpler measurement set-up and measurement principle.

Solutions for semiconductor process, facility monitoring and control

Semiconductor wafer and microelectronics fabrication is a demanding process with little room for mistakes. The industry depends on high-performing monitoring and measurement instrumentation for precise chemical compositions and atmospheric conditions.

Vaisala DRYCAP® Dewpoint Transmitter DMT152

The Vaisala DRYCAP® Dewpoint Transmitter DMT152 is designed for measuring low dew point in OEM applications, even down to -80°C. The excellent long-term stability and reliability of its performance is based on the latest DRYCAP® polymer sensor technology.

DescriptiAs a Principal Scientist at Vaisala, Hannu Sairanen specializes in humidity measurement and applications, including humidity metrology. He has 10+ years of experience in humidity metrology, humidity measurements, and humidity-dependent processes with many publications based on his work in those areas. Hannu holds a doctorate from Aalto University in Finland, with a major in applied thermodynamics.