Application note

Gelatine Evaporation

Gelatine quality and evaporation process control

Gelatine is produced from bones and skins in acid and liming process, and is derived as a protein from selective hydrolysis of collagen.

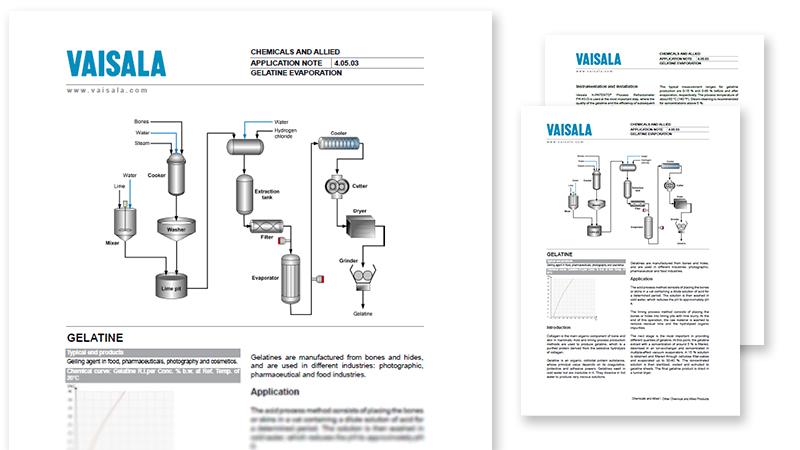

If produced in the acid process, the bones or skins are kept in a dilute solution of acid for a determined period. The solution is then washed in cold water to reduce the pH level to approximately 4.

The liming process involves liming pits with lime slurry where the bones or hides are place into. The raw material is then washed to remove residual lime and the hydrolysed organic impurities.

Next, the gelatine is treated to obtain different qualities. Namely, the gelatine extract with a concentration of around 5 % is filtered, deionised in an ion-exchanger and concentrated in multiple-effect vacuum evaporators. The solution is filtered through cellulose filter-cakes and evaporated. The concentrated solution is then sterilized, cooled and extruded to gelatine sheets. The final gelatine product is dried in a tunnel dryer.

The Vaisala Polaris™ process refractometer is used at the most important step, where the quality of the gelatine and the efficiency of subsequent operations are defined. Learn how the refractometer is used and the details of the gelatine production process from the application note.

Download the application note in PDF by filling the form.

Go back to all Chemicals & Allied Products applications

You can modify your preference settings or unsubscribe at any time here