Brown stock Total Dissolved Solids measurement

to optimize brown stock washers and washing process

The development of Vaisala Polaris PR53SD Process Refractometer for the continuous measurement of dissolved solids content (TDS) in fiber suspensions allows to follow the performance of individual process steps continuously. TDS changes in the feed and outlet stock lines, as well as in incoming and outgoing filtrate lines, can be detected immediately.

Through optimization of the brown stock washing process and raising the black liquor solids content, mills gain immediate profits, cleaner and better quality pulp for bleaching, as well as optimized use of water, chemicals and energy.

In-line process control applications in fiberline and brown stock washing

Brown stock washing (BSW) can be considered the key operation influencing the economics of the pulping process, as well as the environmental load of the mill. The purpose of brown stock washing is to remove both organic and inorganic soluble compounds from the pulp suspension (brown stock) while using the lowest possible amount of wash liquor or water. Vaisala provides process refractometers for measuring and monitoring the Total Dissolved Solids (TDS) content in the pulp suspension.

When examining the overall economic relationship between operating cost and efficiency, the first considerations are maximizing the solids yield due to its heat value in the recovery boiler and minimizing the dilution factor to save steam in the evaporators. The next key factors are the cost of make-up chemicals for replacing sodium losses and the cost of effluent treatment. Other important considerations include evaporator efficiency limitations in many mills and bleach chemical consumption in bleachable-grade mills.

The development of Vaisala Polaris PR53SD Process Refractometer for the continuous measurement of dissolved solids content in a fiber suspension has made it possible to follow the performance of individual process steps continuously. TDS changes in the feed and outlet stock lines, as well as in incoming and outgoing filtrate lines, can be detected immediately.

Once a mill has the appropriate number of in-line total dissolved solids measurements, it can calculate and optimize its brown stock washing variables, such as the optimum Dilution Factor (DF), Displacement Ratio (DR), relative washing loss (1-Y), and the entire plant Efficiency Factor (E). This enables the implementation of upper-level control in order to achieve the benefits of the full optimization of brown stock washing operations.

Typical applications in brown stock washing

Digester washing zone and blow line

TDS measurement in the blow pulp suspension after the digester enables monitoring of the diffuser operation. Together with other measurements (e.g. filtrate and flush liquor), this provides the mill with the ability to control the performance of the washing zone in the digester. In addition, TDS measurement in the blow line allows the performance of the digester to be monitored, ensuring that it yields the correct concentration. The combination of these measurements facilitates the continuous calculation of the mass balances of the digester.

Pulp feed to washers

Accurate and real-time TDS measurement within the feed pulp allows a quick response to process changes and prevents disturbances from being carried over into subsequent washing stages. Process variables, such as the dilution factor, can be controlled in accordance with the properties of the inlet pulp, and mass balances can be continuously monitored.

Washing stage

At this stage, in-line TDS measurements provide better control and help to determine the optimum dilution factor, right operation consistency, and optimum concentration of solids in the stream to the recovery boiler. This prevents excess consumption of water in the washers, thus reducing the energy requirements of the evaporator and the need for make-up chemicals.

Pulp to oxygen delignification (OD)

The cost and performance of the OD process can be optimized using in-line TDS measurements. Wash loss reduction in the inlet pulp to the reactors decreases the amount of alkali. Alkali is consumed in neutralization reactions of the organic acids. In addition, the temperature of the reactor can be optimized, and the amount of oxygen decreased.

Pulp discharge to bleaching

Reliable continuous measurements of wash loss in the discharge pulp make it possible to control the success of the washing process. By minimizing the wash loss, the subsequent process steps can be optimized. Lower wash loss in the outlet pulp will improve its quality while also decreasing the amount of chemicals required in the bleaching stage. Reliable measurements improve environmental performance and can reduce effluent treatment costs

Benefits of in-line measurement and process control in BSW

- Continuous washing efficiency control

- Improved performance of oxygen delignification and bleaching

- Reduced consumption of additional reagents in the subsequent bleaching stages

- Improved pulp quality

- Less formation of harmful organic compounds in the bleaching stage, less load to effluent treatment

- Improved recovery of cooking chemicals (Na and S) and wood-based dissolved organic materials

- Increased recovery boiler efficiency

- Optimized use of energy

- Enhanced mechanical performance of the washers, longer lifetime

- Improved process runnability

- Moderate initial investment; return on investment (ROI) is relatively fast, about 3-6 months

Applications in the pulp and paper processing

The efficiency and safety of Kraft chemical recovery and fiberline and brown stock washing processes can be significantly improved by measuring in-line, real-time dry solids content. Download our application notes for more information.

Kraft (Sulfate) Pulp Process

Sulfite Pulp Process

Paper Sizing Process

Can't find your application?

Only some examples of our refractometer applications are listed here. There are still hundreds more!

Our application experts will help you. Tell us a bit more by filling the form or contact us.

Brown stock Total Dissolved Solids measurement related products

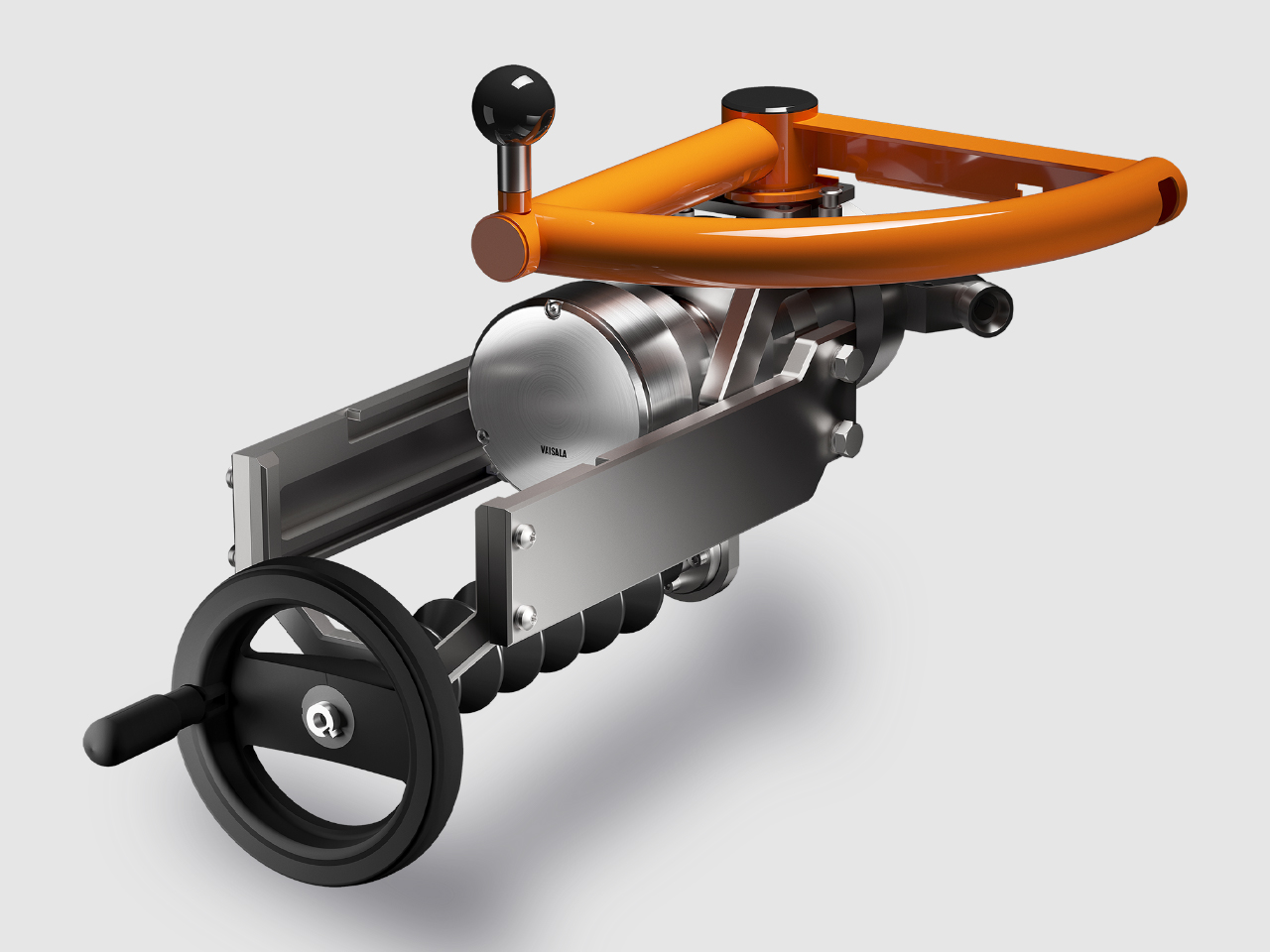

Vaisala Polaris™ PR53SD Process Refractometer

Related resources

Webinar

Importance of brown stock washing and digester dissolved solids optimization for pulp mill efficiency

Register to watchWebinar

Advantages of real-time dissolved solids content (TDS) measurement in fiber suspensions + implementation in individual BSW process steps and upper level process control

Register to watchWebinar

Real-life use cases on control practices and impacts before and after TDS technology implementation in brown stock washing

Register to watchLiquid concentration measurement

Vaisala offers a wide range of products tailored to liquid measuring needs of different industries.

Learn more about the refractometer technology and its applications, and visit the library of product related assets.