Kraft (Sulfate) Pulp: Causticizing

Kraft (Sulfate) Pulp: Causticizing

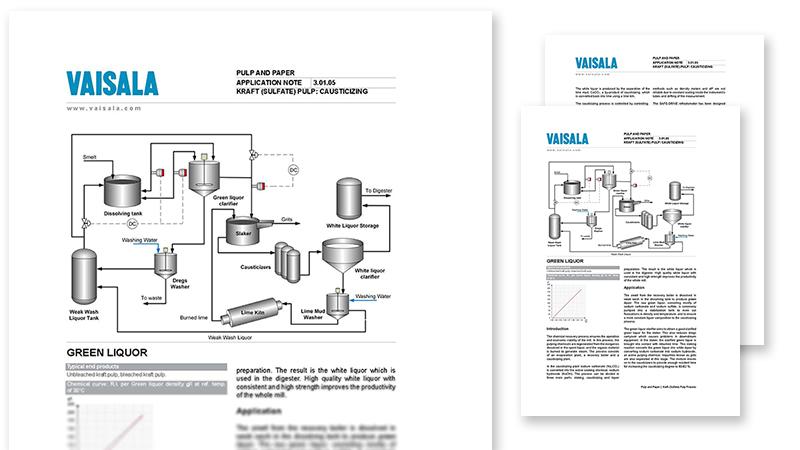

The causticizing process is controlled by controlling the slaker operation, which in turn depends on the concentration of the raw green liquor’s Total Titratable Alkali (TTA). The goal is to stabilize the density or TTA concentration in the green liquor feed to the slaker to avoid over liming and ensure safe operation. TTA measurements in the main green liquor lines (from dissolving tank and clarifier) are required for control purposes.

Efficient causticizing control improves the quality and stability of white liquor, decreases operating costs and increases pulping efficiency. Well-performed lime dosage control reduces the recirculation flow of lime in the process, leading to less lime re-burning in the lime kiln and decreased energy consumption

Controlling black liquor dry solids in feed to recovery boiler

Download our application note to learn how Vaisala Polaris SAFE-DRIVE Process Refractometer PR53SD measures the density or TTA concentration of green liquor at two stages of the process: after the green liquor dissolving tank, and after the green liquor clarifier at the slaker feed.

The refractometer’s sensor is mounted directly in the pipelines allowing real-time and active control to meet the target TTA. Pirssonite formation in the pipe walls does not cause any problems for Vaisala instrumentation technology in this application.

Download the application note in PDF by filling out the form.

Go back to all Pulp, paper and wood applications

You can modify your preference settings or unsubscribe at any time here