Water electrolysis

Elevate the electrolytic hydrogen processes through reliable measurements

Green hydrogen produced by water electrolysis is a sustainable solution for the long-term energy demands.

We are continuously developing new measurement solutions to meet the most demanding needs related to the different water electrolysis processes in hydrogen production.

Read below about our liquid and gas measurement solutions for membrane and solid oxide electrolysis processes, as well as dew point instruments* for hydrogen drying.

*Suitable for setups without ATEX requirements.

Optimal potassium hydroxide (KOH) concentration brings higher conductivity

The efficiency of the electrolysis process is highly dependent on the KOH concentration. Usually about 30wt% KOH concentration is ideal, as conductivity is high, and viscosity is still sufficiently low for efficient current flow through the electrolyte. Too high concentration of KOH could also lead to formation of gas bubbles on the surface of the electrodes, which could further reduce the process efficiency. Thus, it is essential to ensure a stable KOH concentration for the optimal current density. This enables the highest possible conductivity in the water electrolysis process.

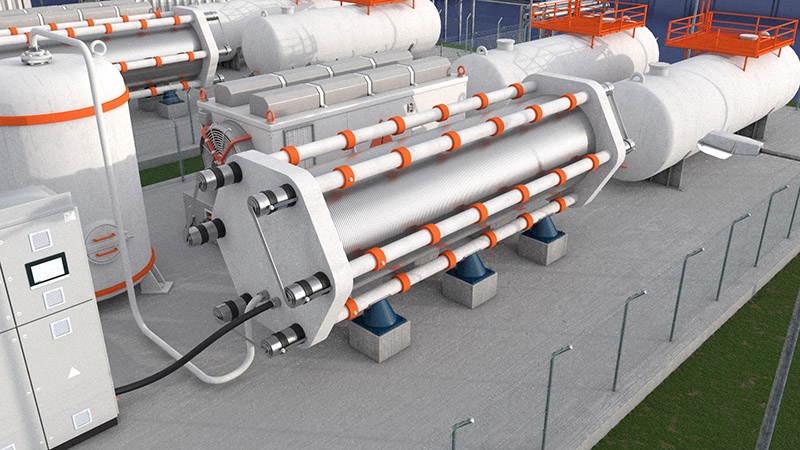

Vaisala Polaris liquid concentration measurement technology is ideal for ensuring a stable KOH concentration, with a product lifetime equal to electrolyzers. Our Polaris refractometers are intrinsically safe, and available with either non-metallic or 316L stainless steel wetted parts that resist KOH corrosion. The full range or temperature compensation withstands large variance from ambient startup temperatures to normal operation temperatures of the electrolyzer such as 90-95°C (194-203°F). You can install the refractometer in the main pipe, a by-pass, or a tank – comprehensive mechanical process specifications are available. Our typical refractometers for electrolysis processes are PR53W, PR53GP, and PR53GC. Please contact us to determine the most suitable refractometer for your setup.

Solid oxide electrolysis process requires multigas measurement

Solid Oxide Electrolysis (SOEC) technology is a way to produce hydrogen and methane from carbon dioxide, water, and electricity. It utilizes carbon dioxide that is captured from industrial emissions, directly from the atmosphere or from biogenic sources such as upgrading of biogas to biomethane. This ensures that the process is carbon neutral or even carbon negative in the case of biogenic and atmospheric CO2. Electricity for the SOEC process is likewise typically renewable in origin: solar power, wind power, hydroelectric or generated in a CHP plant using biomass. In addition, the SOEC technology does not need precious metals or rare earth elements, hence reducing the environmental impact of producing the electrolyzer.

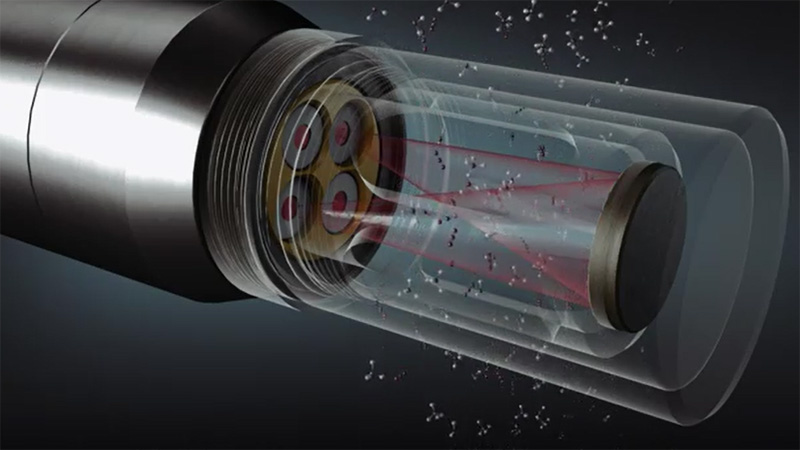

To monitor the carbon dioxide, methane and moisture levels during the process, Vaisala CARBOCAP® MGP261 multigas probe is ideal for real-time measurement of both the feedstock (CO2, RH%) and products (CH4) to enhance efficiency and optimize the process.

The MGP261 is compact in size, Ex certified, and can be installed directly into the gas line without the need for sample treatment.

Hydrogen drying benefits from moisture measurement

The H2 drying process improves the quality of hydrogen gas by preventing corrosion, insulation failure, and combustion issues. Dew point measurement helps optimize this process for better hydrogen quality and lower energy use, as excessive heating of the drying air can be avoided.

The key characteristics of a reliable dew point measurement instrument are long-term measurement stability and reliability. Vaisala DRYCAP® instruments have been developed to meet these requirements.

Our options for isolated setups without ATEX requirements are Miniature Dew Point Transmitters DMT143 & DMT143L (Long), DMP7 for remote installations in tight spaces and DMP8 with adjustable installation depth for pressurized pipelines <40 bars.