Application note

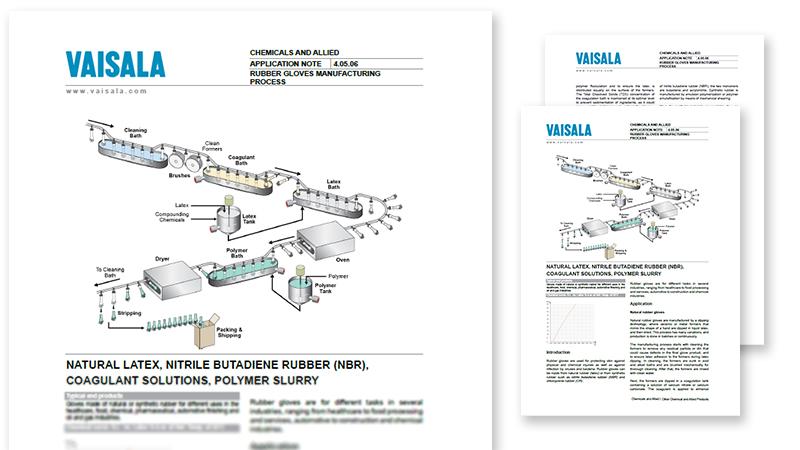

Rubber Gloves Manufacturing Process

Coagulation baths concentration measurement in rubber gloves production

Rubber gloves that are widely used in healthcare, food processing and services, automotive to construction and chemical industries, can be made from natural rubber (latex) or from synthetic rubber such as nitrile butadiene rubber (NBR) and chloroprene rubber (CR).

Natural rubber gloves are manufactured by a dipping technology where ceramic or metal formers that mimic the shape of a hand are dipped in liquid latex, and then dried. The formers are then dipped in a coagulation tank containing a solution of calcium nitrate or calcium carbonate. The coagulant is applied to enhance polymer flocculation and to ensure the latex is distributed equally on the surface of the formers.

After mild drying, the formers are dipped into the latex dipping tank containing compounded mature latex which is a mixture of latex and various compounding chemicals. The concentration of latex is carefully monitored and controlled as it has a crucial effect on the final quality, durability and product specification.

A leaching process follows, where the formers are dipped into hot water to dissolve proteins, water soluble residues and other chemicals from previous steps. Proper leaching of the gloves improves the strength of the latex film but not without replenishment of water to prevent build-up of extracted chemicals.

Vaisala PolarisTM process refractometer is installed at different stages of the rubber gloves line to measure the concentration of dipping baths solutions. The refractometer provides continuous total dissolved solids (TDS) concentration measurement to ensure operation within the specifications and to guarantee high-quality rubber gloves.

Learn more details of the natural and synthetic rubber gloves production from the application note.

Download the application note in PDF by filling the form.

Go back to all Chemicals & Allied Products applications

You can modify your preference settings or unsubscribe at any time here