The new Vaisala Indigo80 handheld device and Vaisala Polaris™ process refractometers – a match made in process heaven

The Vaisala Polaris family of process refractometers has a wide range of uses in processes where liquid concentration measurements are required. You can use a Vaisala Polaris instrument alongside the Vaisala Indigo80 Handheld Indicator to get a range of additional benefits in industrial processes. This blog explores some typical use cases where these benefits make the most difference.

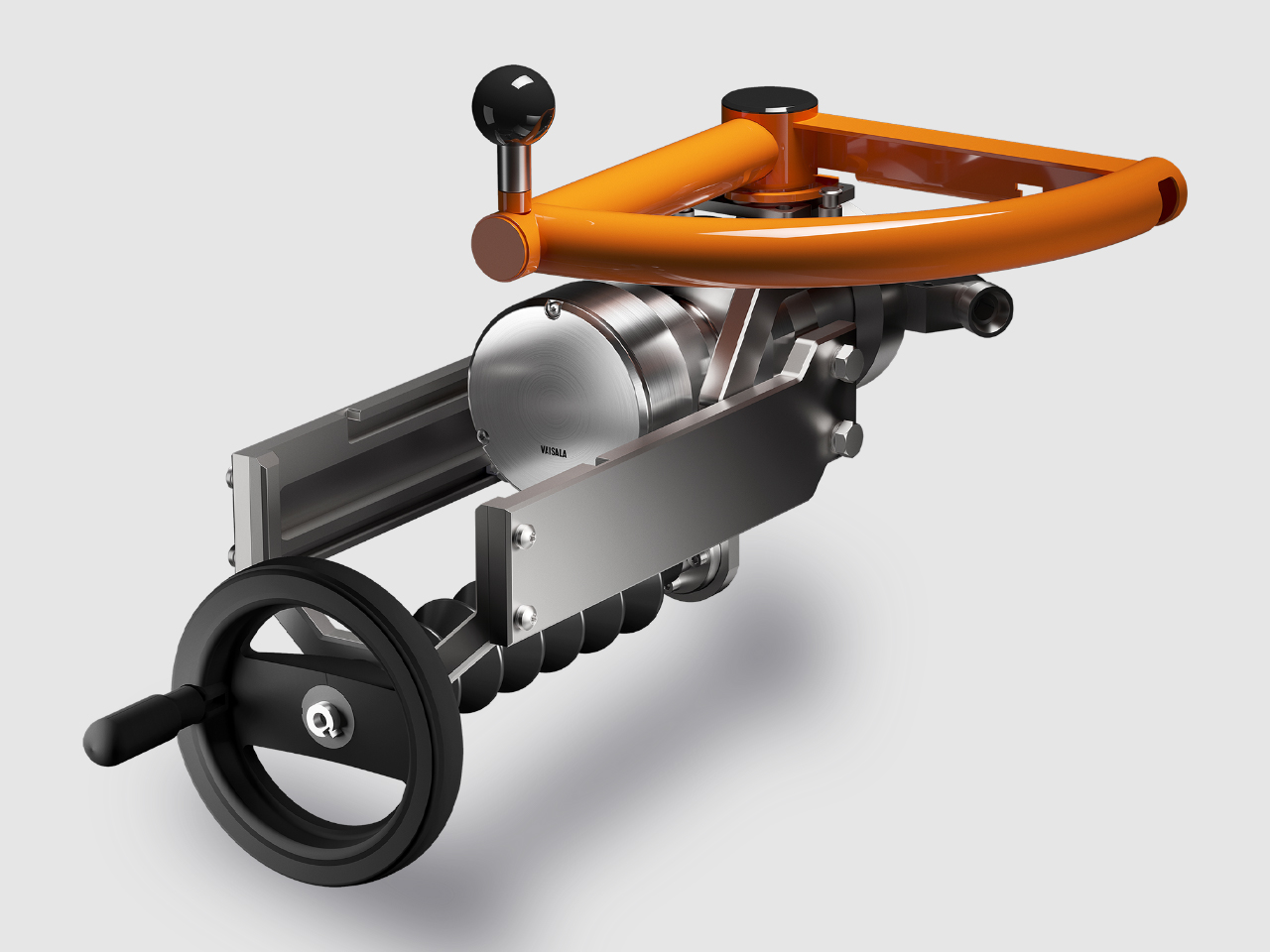

The compact Indigo80 Handheld Indicator is a portable measurement device for field sampling and calibrations, data analysis, and diagnostics. When combined with Vaisala Indigo compatible instruments, it offers stable and accurate measurements of parameters such as humidity, temperature, dew point, carbon dioxide, hydrogen peroxide vapor, moisture in oil, refractive index and liquid concentration even in the face of rapid environmental changes. With exceptional battery capacity, a high-resolution display, and a memory that can hold up to 5.5 million data points, Indigo80 is a convenient way to visualize measurements over a long period of time and inspect readings from installed probes to check if they require calibration. It can also be used for data logging, spot checking, and troubleshooting, with the display providing visualization of data from installed equipment. With process refractometers it is able to display the optical image and other information of the instrument for accurate diagnostics view on the spot.

Indigo80 is compatible with the Vaisala Polaris range of process refractometers, which are used in a broad variety of process industry applications such as crystallization, dilution, distillation, blending, and quality control. These are all applications where liquid concentration measurement is key to ensuring optimal process conditions, product quality, process safety, and regulatory compliance.

Vaisala Polaris uses the fundamental concept of refractive index readings to measure liquid concentrations, helping to maintain safe operations in the pulp industry with black liquor total solids measurement, in ensuring the quality of food and beverages by measuring sugar content, and enabling accurate concentration measurements in chemical production processes, among many other uses.

Let’s look at some use cases that illustrate the benefits of using Indigo80 together with Polaris process refractometers.

1. Configuration and calibration – no downtime for configuring probes

Polaris process refractometers are delivered preconfigured, with concentration coefficients set up for the intended application. With an Indigo80 you can quickly and easily adjust parameters rather than needing to remove the probe from the process to reconfigure it via a laptop. The Indigo80 can also be used to change the signal damping parameters without compromising the process. Having a dedicated handheld device means there’s no need to bring laptops or other devices into the process area, which can be a safety issue or compromise a clean room setup. For verification purposes, Indigo80 gives you an easy way to confirm the reading from the automation system for calibration processes.

2. Data logging – uncovering problems in a process

Many field devices do not store historical data, instead taking snapshot readings that are used in process controls or to generate alarms if process parameters exceed set limits. If an unexpected situation arises and the operator is uncertain what’s causing it, a diagnostic tool is needed. This is where using Vaisala Polaris with Indigo80 can help – as Indigo80 is battery powered, it can be connected to the field device overnight, or for a longer period. The Indigo80 enables data comparison with that of the system in order to determine variations over time to help in diagnostics.

3. Maintenance – identifying when sensors require cleaning

Although Polaris process refractometers rarely require maintenance due to their rugged construction and lack of consumable and moving parts, maintenance might be needed if the optical prism become coated in residue, causing the quality factor to drift. The quality factor is a numerical parameter that indicates the cleanliness of the prism. If drift happens, the unit will need to be removed and cleaned – and Indigo80 can help to identify maintenance needs by logging the quality factor over time. If the quality factor drifts downwards or there are significant variations, it’s a good indication that a spot of cleaning might be needed. Indigo80 can also be used as a display for Vaisala Polaris and other smart probes that don’t have their own displays, with a choice of two views: the current measurement or a graphical representation of the probe’s historical readings.

The Indigo80 and Vaisala Polaris process refractometer are powerful tools for gathering valuable process insights and improving process and end-product quality across a variety of applications. When used together, the benefits are magnified, with Vaisala Polaris gathering accurate concentration data and Indigo80 providing a convenient way to log, access, and visualize this data without the risk of process downtime.

The updated firmware will become available by the end of March. Existing customers will also get the new features by updating the firmware of both Polaris process refractometers and Indigo80 handheld devices.

Learn more about the Vaisala Indigo80 and Vaisala Polaris process refractometers.

Add new comment