How to Read ATEX and IECEx Markings of Humidity Instruments for Hazardous Locations

Hazardous locations are areas where flammable liquids, gases or vapors or combustible dusts exist in sufficient quantities to produce an explosion or fire under normal or abnormal conditions. Typical industries or processes that may have a potentially explosive atmosphere include oil and gas drilling, petrochemical refining and processing, fuel storage and painting. In order for an explosion to take place there has to be fuel – for example an explosive gas such as hydrogen – and some oxidizer such as the oxygen in air. Also a source of ignition energy is needed, for example, a hot surface or an electrical spark.

It is not always possible to remove the oxygen or fuel from the atmosphere. This leads to secondary type of explosion protection, namely avoidance of ignition sources. Using only Ex certified equipment removes the main sources of ignition. Electrical equipment that must be installed in hazardous locations should be specially designed and tested to ensure it does not initiate an explosion, due to arching contacts or high surface temperature of equipment. All equipment certified for use in hazardous areas must be labeled to show the type and level of protection applied.

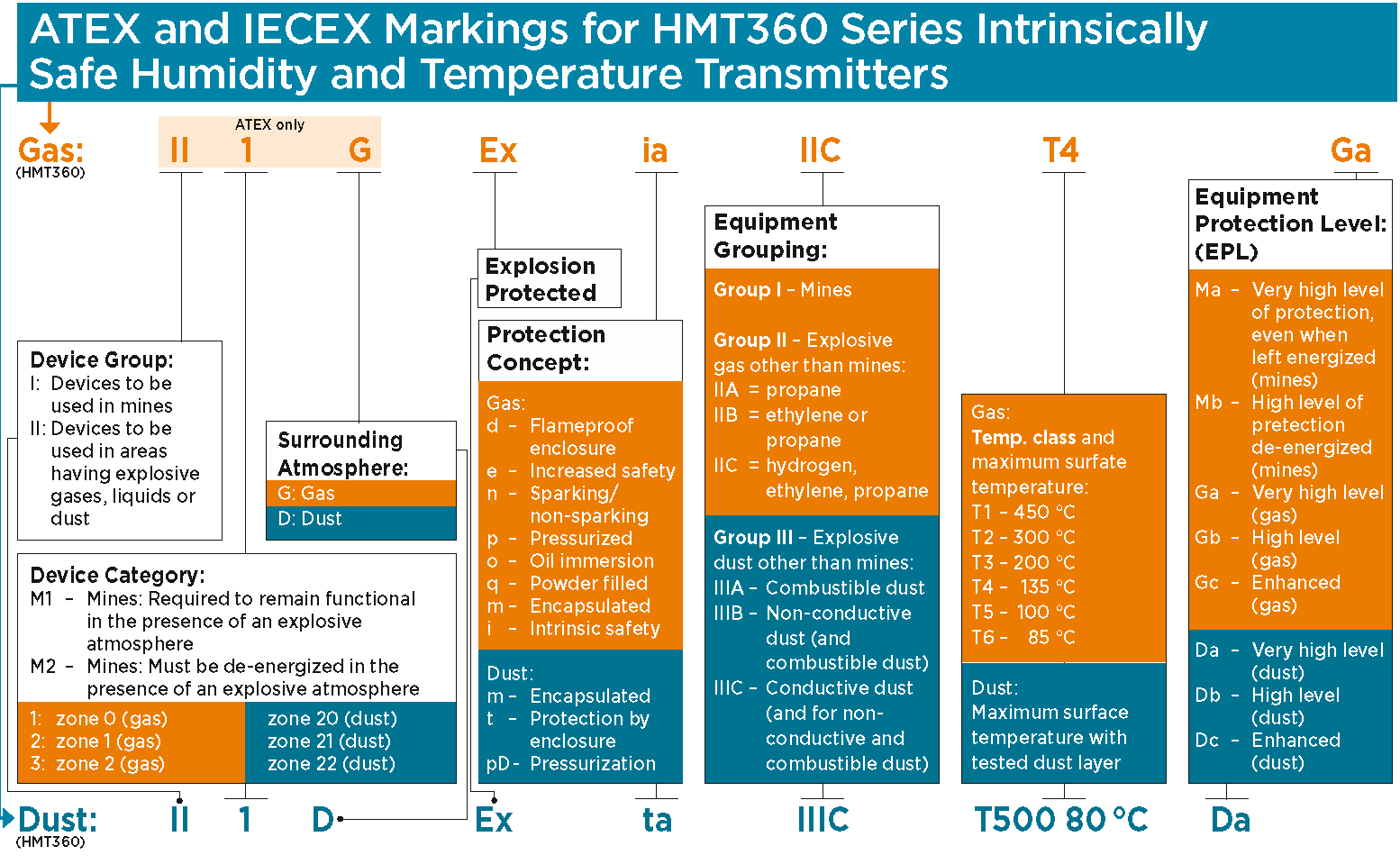

The image above shows typical Ex markings used on nameplates of modern Ex instruments that are certified in accordance of the EU ATEX directive. The marking string can be divided into two parts, because the first part is required by directive 2014/34/EU and only concerns devices with ATEX certificate. ATEX is mandatory for all equipment sold in EU.

The second part is common to both ATEX and IECEx certified devices and it is defined in 60079-0 standards, which specifies general requirements for Ex apparatus. One nameplate can contain both ATEX / IECEx certifications, but it is possible that a device has its own nameplate for ATEX and IECEx.

In addition to the ATEX / IECEX, HMT360 complies with classifications from FM (USA), CSA (Canada), TIIS (Japan), PCEC (China), and TR CU (EAC: Russia, Kazakhstan and Belarus). These have slightly different product markings.

The Vaisala HUMICAP® Humidity and Temperature Transmitter Series HMT360 is the ideal solution for measuring humidity in hazardous areas. All probe options operate safely and reliably even in the most hazardous classifications. The HMT360 transmitters' proven performance and technology conform to rigorous international standards.

The product marking of the Vaisala HUMICAP HMT360 - the Intrinsically Safe Humidity and Temperature Transmitter Series for Hazardous Environments:

GAS: II 1 G Ex ia IIC T4 Ga

DUST: II 1D Ex ta IIIC T500 80 °C Da

The above means that the entire transmitter HMT360 is designed for zone 0 for gas and zone 20 for dusts. Note that both the probe and the transmitter body can be installed into zone 0/20. Naturally, it can be also installed in zone 1 or zone 2.

HMT360 Temperature class is T4 and explosion group IIC meaning that it can be used in area containing almost all gases except carbon disulfide. Read more about the product and download the marking table in a larger size at www.vaisala.com/HMT360.