On May 20, we celebrate World Metrology Day. In honor of metrology and to celebrate metrologists' day, Vaisala and metrology are reflected on one another. What kind of metrology do our customers see us doing, and what else is going on behind the scenes? What does metrology mean for Vaisala?

Metrology for improved sustainability

Taking every measure for the planet is Vaisala's purpose. It has a double meaning in practice: our instruments contribute to improving quality of life through measurements, and our products can be used to improve energy efficiency and sustainability. When Vaisala's values are paired with its purpose, metrology is at its heart. Through metrology Vaisala is able to deliver additional value to our customers through accurate, reliable measurements that can be traced to the International System of Units (SI). The science-based accuracy of Vaisala's measurement instruments is based on state-of-the-art laboratory facilities and a wide range of metrology innovations.

Nearly invisible but crucial

Among measurement instrument users, only a small part of Vaisala's metrology is visible. Obviously, they see the instrument and its documentation. Factory calibration certificates, however, describe the instrument's performance only within a small measurement range. In most cases, our life cycle service teams can provide ISO 17025 accredited calibrations required by the customer. Even so, metrology work is largely invisible.

Tested beyond promise

As part of the product development process, all new products are tested at SI traceable test stations across their entire range with known uncertainties. Through this extensive testing, we can confidently say that Vaisala instruments perform within their specifications throughout their measurement ranges. Furthermore, Vaisala instruments undergo various types of hardware and metrological testing during the R&D phase: Vaisala instruments are exposed to different chemical conditions and then revalidated using SI-traceable testing facilities after the exposures. Late in the product development new instruments are installed at Vaisala's outdoor test field followed by regular returns back to laboratories for inspections. Those interested in satellite images can see our outdoor testing grounds as one "testing facility".

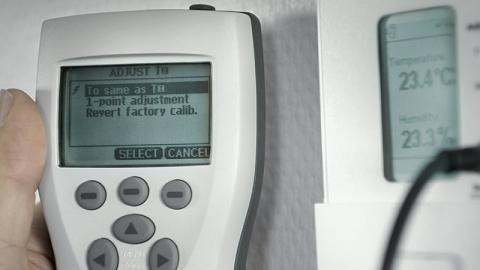

Unbroken chain of calibrations

Several metrology steps are involved in the manufacture of a new product. Sensor chips are manufactured using SI traceable instruments that monitor and control process environments. Sensor chips are tested in specially designed SI traceable test stations during the early stages of production. Vaisala is doing this to avoid scrap in later phases which would lead to higher costs for customers. Final calibrations of the devices take place at the factory calibration stations for the complete measurement instrument. The metrology behind the station, however, cannot be seen. For example, the humidity calibrations are completed using Vaisala's primary humidity standards. Their references are regularly calibrated, so there is an unbroken chain of calibrations to the SI. Additionally, internal comparisons between Vaisala's humidity standards are performed on regular basis, similar to what is done by national metrology institutes.

A commitment to metrology requires more than high-quality and well-designed facilities; it also requires skilled metrology personnel. With the help of highly skilled metrology professionals, Vaisala strives to make the world a better place. This is in line with the theme of World Metrology Day 2024: We measure today for a sustainable tomorrow.

We wish you a precise and accurate World Metrology Day!