Production of Active Pharmaceutical Ingredients (API)

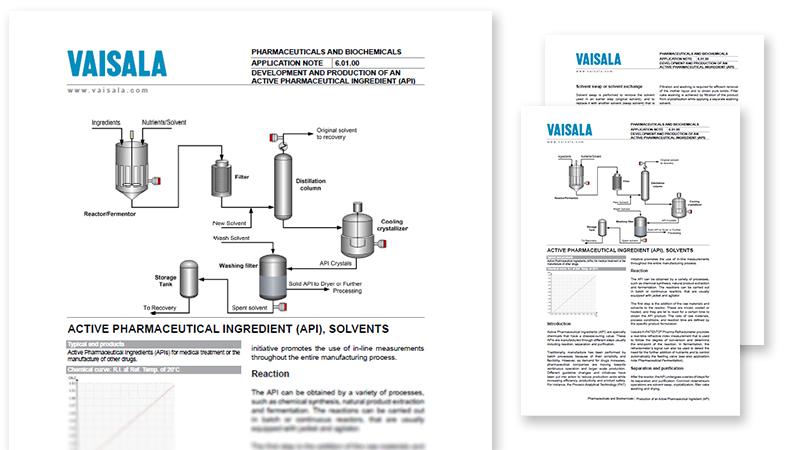

Developing and producing Active Pharmaceutical Ingredients (APIs) includes various processing steps, such as reaction, crystallization, separation and purification, filter cake washing, solvent swap, and solvent exchange.

Production of Active Pharmaceutical Ingredients (API)

Download our application note and learn how, by utilizing real-time concentration measurements by Vaisala PolarisTM Refractometer, pharmaceutical manufacturers can:

- Follow the reaction and determine the correct endpoint

- Automatically control the feeding valves

- Monitor solvent swap operation

- Monitor mother liquor concentration and determine seeding point

- Understand the washing process, create washing profiles, and find the most suitable washing solvent

- Analyze processes and create process profiles for reference in scale-up

- Identify and monitor critical process parameters (CCP)

The application note explains in detail the benefits of using the Polaris refractometer. The note also includes recommended installation points for best performance, and shortly introduces the reliable technology our pharma refractometer is based on.

Download the application note (PDF) by filling the form.

Watch our webinar on The benefits of refractive index (RI) in the development and production of Active Pharmaceutical Ingredients (APIs)

Discover all applications in Pharmaceutical drug manufacturing and biotechnology processes.

You can modify your preference settings or unsubscribe at any time here