Application note

Wet Process Phosphoric Acid Production

Vaisala

In-line concentration measurement and quality monitoring of sulfuric and phosphoric acids

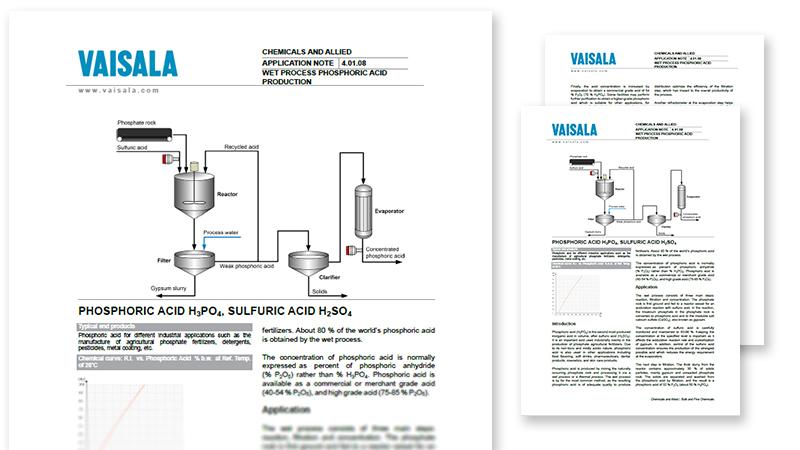

Phosphoric acid, H3PO4, is produced from phosphate rock by wet process or thermal process. 80% of the world’s phosphoric acid is obtained by the wet process. The wet process consists of reaction, filtration and concentration steps. The phosphate rock is ground and acidified with sulfuric acid in the reactor vessel. In the reaction, the tricalcium phosphate in the phosphate rock is converted to phosphoric acid and to the insoluble salt calcium sulfate (CaSO4), also known as gypsum.

The concentration of sulfuric acid must be maintained at 93-98% as it affects the acidulation reaction rate and crystallization of gypsum. In addition, control of the sulfuric acid concentration ensures the production of the strongest

possible acid which reduces the energy requirement at the evaporators.

The next step is the filtration where the solids are separated and washed and the phosphoric acid of 32% P2O5 (about 50% H3PO4) is received. Finally, the acid is evaporated to obtain the commercial grade acid of 54% P2O5 (70% H3PO4). Further purification is required for higher grade of phosphoric acid for use in food, pharmaceutical and cosmetics industries.

Vaisala Polaris™ Process Refractometer helps to

- measure in real-time sulfuric and phosphoric acids concentration in-line, eliminating the need for sampling

- ensure that only phosphoric acid of high strength is produced and less energy at

- the evaporators is consumed

- regulate the heat load in the reactor vessel

- control gypsum crystallization. Optimal crystal size and shape optimize the efficiency of the filtration step, which has impact on the overall productivity of the process.

- reduce the operation costs by monitoring the final phosphoric acid concentration

Learn more details about the unique digital sensing technology and the the phosphoric acid wet process optimization from the application note.

Download the application note in PDF by filling the form.

Go back to all Chemicals & Allied Products applications

You can modify your preference settings or unsubscribe at any time here