Application note

Metal Induction Hardening

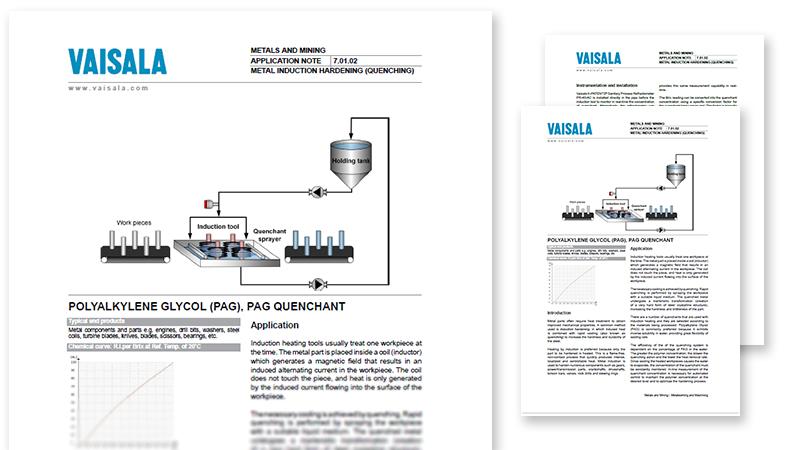

PAG quenchant concentration control in metal induction hardening

For improving hardness and durability of the steel, induction hardening, also known as quenching, is used. This is done by spraying the workpiece with a suitable liquid medium.

Quenchants are selected according to the materials being processed. For example, polyalkylene glycol (PAG) is commonly used due to its inverse solubility in water, providing great flexibility of cooling rate.

The efficiency of the quenching system dependents on the percentage of PAG in the water. The greater the polymer concentration, the slower the quenching action and the lower the heat removal rate are. Since cooling of the heated workpieces causes the water to evaporate, the concentration of the quenchant must be constantly monitored.

Vaisala PolarisTM process refractometer provides in-line measurement of the quenchant concentration which is necessary for automated control to maintain the polymer concentration at the desired level and to optimize the hardening process.

Learn more details of the quenching process from the application note.

Download the application note in PDF by filling the form.

Go back to all Chemicals & Allied Products applications

You can modify your preference settings or unsubscribe at any time here