Optimizing PET production with refractive index measurement of Ethylene Glycol in recycling lines

Ethylene Glycol, with the chemical formula (CH2OH)2, is a versatile compound used in various industries. Its typical end products include synthetic fibers, thermoforming applications, engineering resins, and PET bottles.

The Importance of Polyethylene Terephthalate (PET)

Polyethylene Terephthalate (PET) plastic is a crucial material used to produce fibers and yarn, engineering plastics, photo and packing film, and beverage and food containers. The majority of the world’s PET production is for synthetic fibers (over 60%), with bottle production accounting for around 30% of global demand. In textile applications, PET is generally referred to as polyester, while in packaging, it is known as PET.

PET Production Processes

The production of PET involves reacting the monomers Terephthalic Acid (TPA) and Ethylene Glycol (EG) in the presence of a catalyst. However, not all the EG reacts during this process. The excess EG, along with other minor reaction products like Propylene Glycol (PG) and Triethylene Glycol (TEG), are recovered and recycled back into the reactor feed.

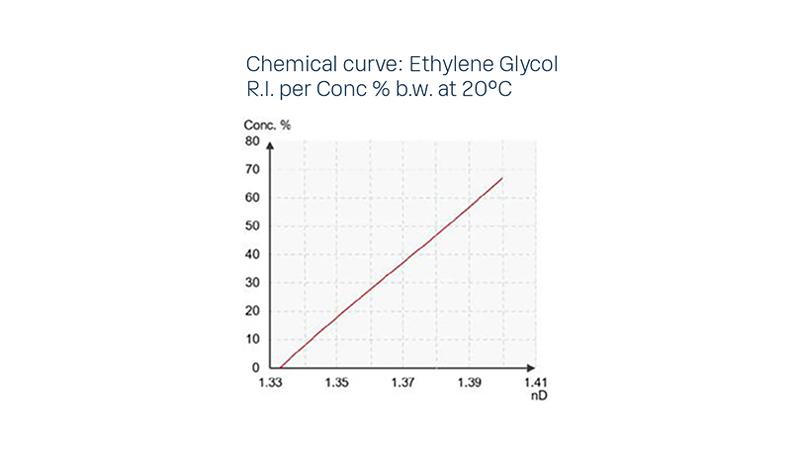

Measuring Process EG Concentration

Accurate measurement of EG concentration in the recycling line is essential to maintain the desired reactor feed level. The concentration of the EG feed significantly affects the quality and opacity of the polymer product.

Process Refractometer Instrumentation & Installation

The Vaisala Polaris™ PR53GP Process Refractometer is used to measure the concentration of Ethylene Glycol in the recycle stream. This measurement helps adjust the feed ratio of fresh EG to ensure the correct quantity is fed to the reactor.

The typical measurement range is from 90% to 100%, with process temperatures ranging from 20ºC (68ºF) to 30ºC (86ºF). An automatic prism wash with steam is recommended for this application. Hazardous and intrinsic safety approvals are available when required.

With a robust, non-welded body construction suitable for demanding applications, the Polaris PR53GP Process Refractometer also supports an optional flange-mounted pipe flow cell accessory for secure installation in various pipe sizes. Additionally, Vaisala Polaris process refractometers are Indigo compatible, offering expanded features such as data logging, wash control, settings adjustments, measurement parameters, diagnostics, and service updates.

Add new comment