Why Do We Measure CO₂ in HVAC Applications?

Measuring CO₂ in HVAC applications

Heating, ventilation, and air conditioning (HVAC) is typically not considered a challenging application area when it comes to CO₂ sensors. While it’s true that ambient conditions are mostly benign, sensors still need to be reliable, easy to maintain, and offer long-term measurement stability. In this post I discuss why CO₂ needs to be measured at all and how demand-controlled ventilation (DCV) works, before moving on to look at how measurement helps maintain wellbeing in a building and how it impacts operating costs.

Why do we measure CO₂ in HVAC applications?

While the most common reason for measuring CO₂ is to save energy, the growing body of evidence demonstrating the direct link between indoor air quality (IAQ) and human wellbeing means that measurement is becoming important for maintaining healthy and productive working environments, too. Compliance with regulations is another driver, particularly if building owners are pursuing certifications that require the use of DCV and/or CO₂ measurement.

How does DCV work?

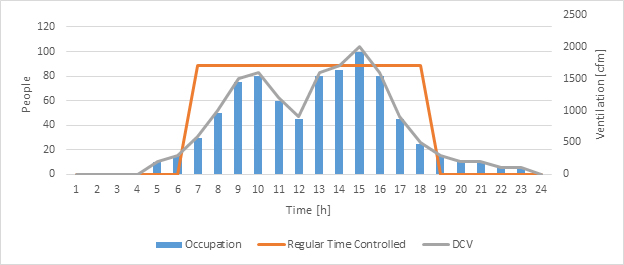

The graph above illustrates the differences between regular time-controlled ventilation and DCV. The blue bars show the occupation level of a space such as an office over the course of a day, while the orange line shows how regular time-controlled ventilation works. In this case ventilation is time controlled between 7 am and 6 pm to save energy by not ventilating at night. The gray line illustrates how DCV works with CO₂ measurement. The CO₂ concentration in a room is measured with sensors and the amount of fresh air is controlled to maintain the concentration at the desired level. The amount of fresh air or ventilation varies according to the building’s occupancy level.

Regulatory considerations for CO₂ sensors in HVAC applications

One of the most important standards in relation to HVAC applications is the ASHRAE 189.1 green building standard, which places strict requirements on CO₂ sensors in terms of accuracy and requires either that they should be capable of measuring outdoor CO₂ concentration or that the concentration should be estimated based on local statistics. In practice this means that many people opt for an outdoor sensor instead.

One of the longest standing regulations is the Californian Energy Commission’s CEC-400-2008-001 standard (Efficiency standards for residential and non-residential buildings). The LEED v.4 green building standard awards credits for CO₂ measurement, with two credits available for CO₂ monitoring in occupied spaces. There are also requirements relating to the accuracy, calibration interval, and maintenance of sensors – something that we are seeing more and more of, and which makes perfect sense. Why demand measurement if you are not demanding maintenance too?

Indoor Air Quality (IAQ) is an emerging topic. For example, the WELL building standard from the International WELL Building Institute is largely based on the LEED and ASHRAE standards. Currently the focus is shifting away from technical requirements more towards occupant wellbeing. In 2010 the World Health Organization published an indoor air quality guide that includes guidelines for selected pollutants and discusses their potential health risks.

The impact of HVAC measurement on building operating costs

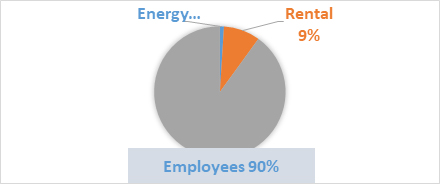

A breakdown of operating costs in a typical office building might look something like this:

Energy costs account for about 1% of the total operating costs of a building, with rental or capital costs totaling 9%, and employee wages 90%. This means that employee wellbeing and productivity is probably the most important consideration in relation to HVAC. Not optimizing your HVAC systems with the help of CO₂ measurement might hit you in the much bigger 90% slice by reducing productivity.

The link between CO₂ levels and employee productivity

Research has shown that CO₂ concentration has a big impact on human cognitive performance. One study conducted by a group from Harvard looked at how specific skills were affected by varying CO₂ concentrations. The study found that skills such as crisis response, information usage, and strategic thinking were significantly impaired even at a concentration level of 1000 ppm, which is considered to be a healthy level to work in.

Elevated CO₂ levels could result in impaired employee learning, decreased productivity, poor decision-making, mistakes, and even hazardous situations. In general, the research seems to agree that good indoor air quality can contribute to a significant increase in employee productivity.

In the next blog in this series we’ll look at the unique advantages of Vaisala’s CARBOCAP® sensor technology in HVAC applications.

Browse our selection of all the HVAC instruments or view them on our HVAC site.

Comment

//Hans

Add new comment