Vaisala PEROXCAP® Technology

Innovative technology for sensing vaporized hydrogen peroxide, designed for bio-decontamination applications.

The unique PEROXCAP® technology enables accurate measurement of multiple parameters in vaporized hydrogen peroxide bio-decontamination. Probes use two capacitive thin-film polymer HUMICAP® sensors to provide high accuracy, excellent long-term stability, and negligible hysteresis in demanding high-concentration vH2O2 applications in atmospheric pressure.

The HUMICAP® sensor is a capacitive thin-film polymer sensor consisting of a substrate on which a thin polymer film is deposited between two electrodes. The polymer film absorbs or releases vapor according to humidity changes in the environment. As the humidity changes, the dielectric properties of the polymer film change, as does the capacitance of the sensor. The probe's electronics measure the capacitance of the sensor and convert it to a humidity reading. The upper electrode is made of corrosion resistant conductive material that protects the active material of the sensor from dust, dirt, and conductive particles. The thin film polymer is sandwiched between two electrodes. The conductive layer allows water and H2O2 vapor to pass through.

PEROXCAP® uses two HUMICAP® sensors, one with and one without a catalytic layer. The thin-film polymer absorbs water and H2O2 vapor. The amount is proportional to the ambient relative humidity (sensor with catalytic layer) or relative saturation (sensor without catalytic layer) depending on the sensor. Learn more about HPP270 series probes.

Intelligent PEROXCAP® measurement technology

One unique feature of PEROXCAP® is that it provides the critical relative saturation value. Water (H2O) and hydrogen peroxide (H2O2) have similar molecular structures, however, while relative humidity (RH) indicates the level of water vapor in the air at a given temperature, relative saturation is the level of water and hydrogen peroxide vapor. Air that contains hydrogen peroxide vapor will condense before 100% relative humidity, which is why relative saturation allows you to predict condensation.

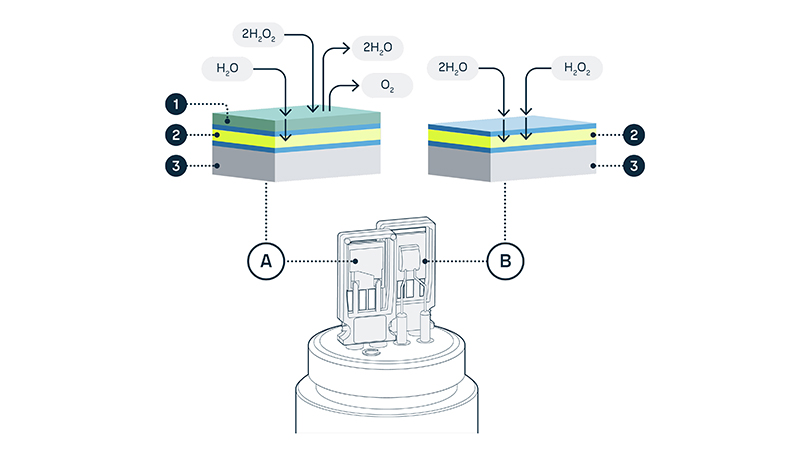

Operating principle of PEROXCAP measurement

HUMICAP® sensor with a catalytic layer under the probe filter. This sensor only senses water vapor.

HUMICAP® sensor without a catalytic layer under the probe filter. This sensor measures the air mixture with both hydrogen peroxide vapor and water vapor.

- Catalytic layer over the thin-film polymer decomposes hydrogen peroxide into water and oxygen and prevents it from entering the sensing polymer.

- Thin-film polymer between two electrodes.

- Alumina substrate.

Chemical purge & sensor vitality for repeatable measurements

The PEROXCAP® sensor has two unique features that ensure reliable measurements:

- Chemical purge: The probe heats up at intervals to maintain measurement performance and lengthen the sensors’ lifespan. Rapid heating of the sensor also removes impurities.

- Sensor vitality: Evaluate sensor performance using the “Sensor Vitality” value. Accessible through Vaisala Insight software, sensor vitality is displayed as a percentage. We recommend replacing HPP270 series probes when this value reaches ≤ 40%.

Multiple measurements for comprehensive bio-decontamination monitoring

Combining the PEROXCAP® sensor with an additional temperature sensor allows several measurement parameters: hydrogen peroxide vapor concentration, temperature, and humidity, referring to both relative humidity and relative saturation.

- HPP271 probes measure H2O2 vapor concentration (ppm) and temperature dew point.

- HPP272 probes measure H2O2 vapor concentration (ppm), temperature, dew point, vapor pressure, and humidity as both relative saturation and relative humidity.

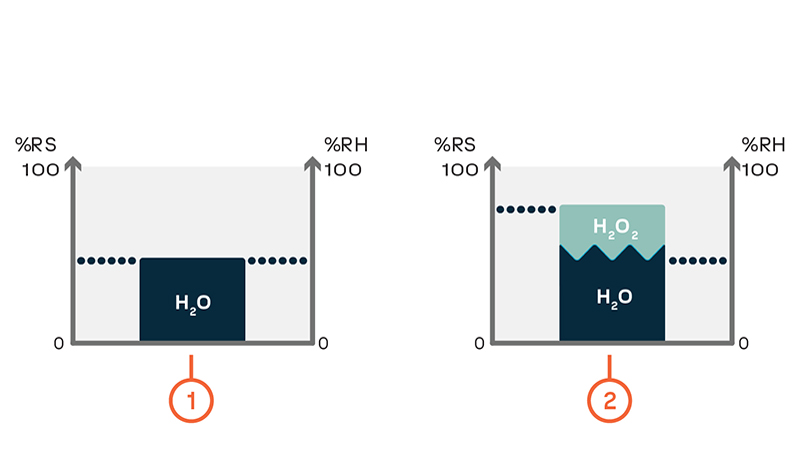

PEROXCAP'S critical difference: Relative Saturation

- Space without H2O2 vapor. When H2O2 vapor is not present, relative saturation equals relative humidity.

- Same space with H2O2 vapor introduced. Relative saturation is higher than relative humidity.

- For example, at 20°C with an H2O2 concentration of 500 ppm, the humidity level 25%RH is equivalent to 60%RS. When this gas mixture starts to condense, i.e. when RS is 100%, RH is 45%.

Traceable H2O2 factory calibration

Every PEROXCAP® sensor is manufactured in Vaisala's own cleanrooms and individually calibrated at the Vaisala factory. Both H2O2 and RH calibrations are traceable to international SI units which ensures that the measured values represent the real environment. You can also calibrate your own HPP270 series probes.