Che cos'è il punto di rugiada e come si misura?

Cos'è il punto di rugiada?

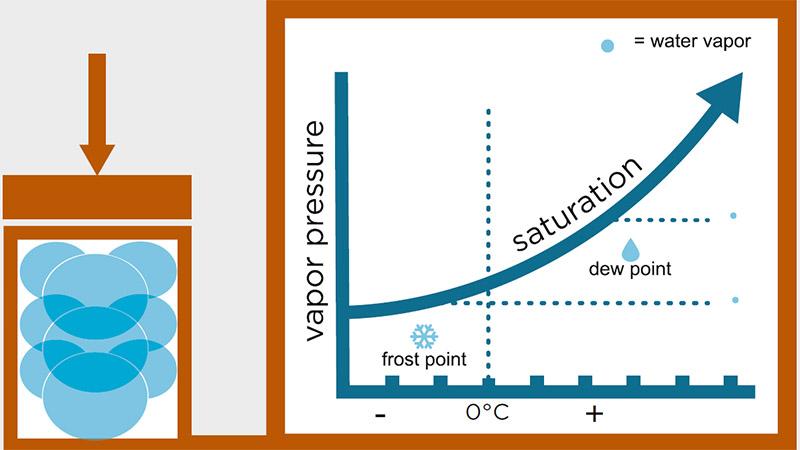

Il punto di rugiada è la temperatura alla quale l'aria deve essere raffreddata affinché il vapore acqueo in essa contenuto si condensi in rugiada o brina. A qualsiasi temperatura, l'aria può trattenere una quantità massima di vapore acqueo, detta pressione di saturazione del vapore acqueo. Se viene aggiunto ulteriore vapore acqueo oltre questo limite, si verifica la condensazione.

Perché l'umidità può causare problemi?

La condensazione nell'aria pressurizzata è problematica perché provoca ostruzioni nelle tubazioni, guasti ai macchinari, contaminazione e congelamento.

Qual è l'effetto della pressione sul punto di rugiada?

La compressione dell'aria aumenta la pressione del vapore acqueo e, di conseguenza, il punto di rugiada. È importante tenerne conto se si sta spurgando l'aria nell'atmosfera prima di eseguire una misurazione. Il punto di rugiada nel punto di misura sarà diverso dal punto di rugiada nel processo.

Qual è l'intervallo tipico del punto di rugiada?

Le temperature del punto di rugiada nell'aria compressa vanno dalla temperatura ambiente fino a -80°C, talvolta persino fino a valori inferiori in casi speciali. I sistemi di compressione senza capacità di essiccazione dell'aria tendono a produrre aria compressa satura a temperatura ambiente. I sistemi con essiccatori a refrigerazione fanno passare l'aria compressa attraverso uno scambiatore di calore raffreddato, provocando la condensazione dell'acqua dal flusso d'aria. Questi sistemi producono tipicamente aria con un punto di rugiada non inferiore a 5°C. I sistemi di essiccazione ad adsorbimento assorbono il vapore acqueo dal flusso d'aria e possono produrre aria con un punto di rugiada di -40°C e, se necessario, più secca.

Come fare per misurare il punto di rugiada in modo affidabile?

- Selezionare lo strumento con l'intervallo di misura corretto.

- Comprendere le caratteristiche di pressione dello strumento per il punto di rugiada: gli strumenti Vaisala sono adatti per l'uso alla pressione del processo, ma sul mercato esistono anche dispositivi che non lo sono. Possono essere installati per misurare l'aria compressa dopo che è stata espansa alla pressione atmosferica, ma il valore del punto di rugiada misurato dovrà essere corretto se il punto di rugiada in pressione è il parametro di misurazione desiderato.

- Installare il sensore correttamente, seguendo le istruzioni del produttore. Non installare sensori del punto di rugiada all'estremità degli stub o di altri componenti di tubi "senza uscita" dove non vi è flusso d'aria.

Per ulteriori informazioni, scaricare la Guida digitale sull'aria compressa di Vaisala oppure contattaci.

Comment

Thank you for contacting us. Sulphur acid is a harmful chemical (it corrodes the sensor easily) that must be kept away from the dew point transmitter. If the exposure of the Sulphur acid can be minimized, then you can choose the right product depending on the dewpoint measurement range you are looking for. One useful chart to choose the right product can be found here: https://www.vaisala.com/sites/default/files/documents/CEN-G-CompAir-Product-Brochure-B211208EN.pdf.

Best regards

Juhani, Product Manager

Thanks for contacting us and showing your interest in dew point measurements. The capacitance signal is measured by converting it first to frequency, where the sensor is a variable capacitance component in the oscillator circuit. This frequency is then counted and converted to relative humidity based on the sensor calibration and linearization (this part is based on the sensor model and other proprietary algorithms that are not public, unfortunately). Please note we always measure relative humidity, and therefore, we need also precise temperature reading that is measured on the humidity sensor surface. This is a normal resistive (pt100) measurement.

With a help of this document, you can derive the dew point calculation based on the measured RH and T: https://www.vaisala.com/system/files/documents/Humidity-conversion-formulas-Technical-eBook-B210973EN-L.pdf

I hope you will also find answers to other humidity-related calculations like absolute humidity, pressure-dependency, and other humidity formulas under the same document.

Best regards

Juhani

https://www.vaisala.com/en/lp/make-your-job-easier-humidity-conversion-formulas, or then you

can register for our webinar: https://www.vaisala.com/en/events/webinars/lp/real-life-use-cases-humidity-calculations

I hope the Humidity Conversion Formulas eBook and our humidity calculator tool will be helpful! Both are free.

Please guide how to choose

https://www.vaisala.com/en/lp/download-vaisala-compressed-air-eguide

To find out the dew point in a certain temperature, pressure, and humidity can be solved relatively easy by using e.g. the Vaisala Humidity Calculator: https://www.vaisala.com/en/measurement/humidity-dew-point-and-moisture. With this free tool we can calculate how much the dew point maximum and minimum are. The maximum dew point happens under higher pressure, higher relative humidity and higher temperature. If we put 7 bar, 80 % RH, and 50 degrees Celsius to the Humidity calculator, we can see the calculated dew point temperature is about 45 degrees C. So, if the gas is cooled down to 45 degrees C, the condensation happens. On the other hand, if our conditions are 6 bar pressure, 60 % RH and 25 degrees C, the dew point temperature would be then about 17 degrees C. Based on this information, the dew point temperature is between 17… 45 degrees Celsius depending on the conditions.

Wanted a few clarification:

a) If the medium tested for dewpoint have a higher range than the analyzer used, will the analyzer give a lower reading instead as it is beyond the accuracy region?

b) Can dry gases like argon & nitrogen be used to test dewpoint with the Vaisala DMP74B type analyzers?

A) If the real frost point (dew point below zero degrees Celsius) is lower (drier) than e.g. the DMP74B, the instrument typically shows the lowest possible reading (with this product the frost point reading goes somewhere to -74 degrees Celsius because the sensor cannot anymore detect the drier condition.

B) Argon and nitrogen are both inert gases and can be measured with Vaisala capacitive thin-film sensor technology. Please note that the pressure of the measured gas has an influence on the dew/frost point and should be inputted to the MI70 handheld to compensate for the pressure effect (the DMP74B cannot measure the gas pressure itself but you need to tell it to the instrument if the pressure is not ambient, i.e. 1 bar(absolute)).

As far as I know, our ouput is in analog (the value is between 0 to 4095). Is there a conversion chart or formula that will calculate the output into dew point correctly?

Analog output scaling depends on the product you have purchased. Based on the given number you are referring to output figures of analog to digital converter. To get your signal correctly converted you need to first understand what kind of output is selected in DMT143 you are using. If no changes are done to the product it can be done by comparing the configuration code of DMT143 to the order form of DMT143 found at docs.vaisala.com. To be 100% sure the product used can tell it’s scaling through the digital bus. DMT143 scaling could be for example be set such that output is 0 to 5 Volts and range is -70 to +60’C. This means that when the transmitter shows 0 Volts output corresponds to -70’C. If output is 5 volts then it corresponds +60’C dew point. If the transmitter outputs 2.5 Volts then it would correspond -5’C dew point.

After you have determined the scaling of DMT143 you need to make sure that how your analog-to-digital converter is scaled and how analog connections are made. For example, if 12 bit AD converter is able to read the whole 0 to 5 Volts output it means that when reading is decimal 0 output of the transmitter is 0 Volts which is the lower range value. If the reading is 4095 it means a maximum of 12 bit converter it means the transmitter outputting 5 Volts which is the maximum range value. If the output is 2047 it means that the transmitter outputs 2.5Volts which is then the middle of the range.

Issues could be that for example if an analog connection is scaled for 0 to 5 volts but the transmitter scaling is 0 to 1 volts it means that only one-fifth of AD converter capability is used and when the signal shows 819 it means that the transmitter outputs 5 volts which is maximum range value.

Best Regards,

Antti Viitanen

Product Manager

Vaisala

1) We keep the compressed air's temperature above the dew point to keep the water vapour in the air

or

2) We keep the compressed air's temperature at or below the dew point to allow the water vapour in the air to condense out, and if so where does that water go to?

I apologize for the late reply, there have been a few comments gone in our Comments, and come up now. 😯

Compressed air should be dried at all times to e.g. prevent corrosion and bacterial growth in the compressed air system, and to cancel free water in the air itself (any water spray or droplets are a sign of bad quality compressed air). There are different drying methods.

The most common (low-cost) drying method is a refrigerant dryer that cools the air close to the freezing point. The cool air dew point then directly equals the air temperature because the cold air cannot hold water anymore and all excess water can be removed by draining it out of the system.

The cool air is saturated by water meaning the RH is 100 %. After the drying, the air is warmed again, when the relative humidity decreases (hot air can hold more water again). The Vaisala DMT132 is a suitable product for refrigerant driers. With a desiccant drier, it is possible to achieve drier compressed air.

You can tell the actual process pressure for the DMT143 by using the serial line and XPRES command. The DMT143 can calculate the actual dew point/frost point temperature, converted to atmospheric pressure.

Best regard, Juhani Lehto

Typical solution is that the dryer is controlled by the online dew point measurement. For example, the desiccant dryer regeneration cycle has been traditionally controlled based on time (assumption when the drying agent needs regeneration). A much better way is to switch dryer towers based on the real moisture inside the tower and that can be detected by measuring the outlet of the dryer. As soon as the output gets moisture it is time to switch. This saves energy and money because the tower drying is based on real-time measurement. I recommend reading this article about compressed air drying: https://www.vaisala.com/en/lp/compressed-air-eguide-benefit-industrial-measurements This document also contains a list of suitable dew point transmitter that fits in your dew point range.

Best regards, Juhani Lehto