Dew point temperature – What does it mean and how can dewpoint temperature be calculated?

Following on from our previous post on relative humidity (RH), let’s look at the second most commonly used humidity parameter – dew point temperature. This is the temperature to which air must be cooled to become saturated with water vapor, and one easy way to understand this phenomenon is to think about taking a shower. If the hot and cold pipes in your shower aren’t insulated, you may have noticed that water droplets form on the surface of the cold pipe. So, what’s happening here?

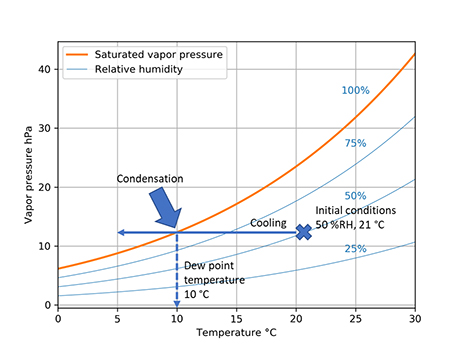

Let’s assume that your bathroom is at 50%RH with a temperature of 21°C. When you turn on the shower, the flow of cold water begins to lower the surface temperature of the pipe and cool the air around it. At a certain temperature we can detect that condensation has started to form, meaning the surface temperature of the pipe has dropped to the point where the surrounding air is no longer able to hold the humidity in gaseous form. This is the dew point temperature.

Why is dew point temperature a useful parameter?

Dewpoint temperature is a useful parameter in many industrial humidity applications. It is often used to measure dryness in applications such as plastics and compressed-air drying , where the relative humidity is typically below 10%RH. It is an industrial de facto to call these types of low humidity instruments as dew point meters. This is an ideal application area for Vaisala DRYCAP® technology.

In addition to dry applications, it’s important to point out that dew point temperature is also a useful parameter in air conditioning and ventilation applications, as well as in high-humidity applications.

Unlike relative humidity, dew point temperature is not dependent on temperature. Let’s take the example of a cleanroom where the control target is set to 40(±2)%RH at a temperature of 20(±1) °C. In these conditions relative humidity may not be an ideal control parameter: as RH is dependent on temperature, it would be virtually impossible to dry or humidify the space while trying to maintain a stable temperature at the same time. The solution is to use dewpoint temperature as the control parameter instead. A relative humidity of 40%RH at 20 °C equals a dewpoint temperature of 6.0 °C. With a narrow dewpoint control band it may be easier to control the environment and save energy.

Another use case is high-humidity applications, where the condensation that forms on the measurement sensor can make it impossible to take measurements until the sensor is sufficiently dry. This can be avoided by using a solution such as the Vaisala HUMICAP® Humidity and Temperature Probe HMP7, which keeps the humidity sensor at an elevated temperature to prevent condensation forming. This ensures reliable and repeatable dew point temperature measurement even in a condensing environment. An example of an application where this functionality is especially useful is PEM fuel cells, where high humidity is essential to maximize the efficiency and lifetime of the cell.

As seen in the previous example, the dew point temperature is a function of saturated vapor pressure. The calculation becomes a little more complicated when we take the environmental pressure into account, which is important, for example, in compressed air applications. While dew point temperature is not dependent on temperature, it is dependent on pressure: the higher the pressure, the higher the dewpoint temperature. One practical tool for playing around with these parameters is the Vaisala humidity calculator.

Access our humidity calculator or contact us for more information.

Vaisala humidity calculator

Relative humidity, absolute humidity, wet-bulb temperature, enthalpy, water concentration, and many more. Humidity calculations and conversions made easy.

Joni Partanen is a Product Manager at Vaisala. He is responsible for the development of humidity and vaporized hydrogen peroxide measuring products. He has over 16 years of experience in process industry measurement technology, industrial engineering, and instrumentation. Joni holds a Bachelor of Engineering degree in Automation Technology.